Maker Personalized Drawer Paper Boxes for Mug Cup Packaging

This drawer paper box has become the preferred solution for mug packaging through its balanced design of functionality and branding, highly flexible customization capabilities and compliant production system. It can not only increase the added value of products, but also help the brand convey its core values of environmental protection, high-end and innovation.

Description

Customised Personalised Drawer Paper Boxes Mug Packaging Product Description

1. Structural Design and Ergonomic Optimisation

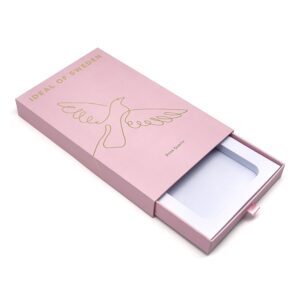

Drawer Paper Boxes Pull-Out Design

- Utilises a drawer paper boxes structure, with the outer shell and inner box precisely aligned via sliding rails, allowing for smooth one-handed retrieval of the mug.

- Suitable for retail display scenarios, the drawer fully opens to visually showcase the product while maintaining overall aesthetic appeal when closed.

2. Shock Protection and Space Optimisation

Tightly Fitting Box Body and Inner Lining

- The box body is precisely die-cut according to the mug’s dimensions, with the inner lining tightly wrapping around the mug to effectively absorb transport vibrations.

- The compact box shape eliminates redundant space, reducing storage occupancy by over 30% and lowering logistics costs; no additional fillers are required during unboxing, enhancing the unboxing experience.

3. Visual Design and Brand Value Communication

- Vibrant Orange Primary Colour

- The box features a warm orange colour, presenting a warm and vibrant visual tone that aligns closely with coffee and home use scenarios.

- Surface finishes can include gold foiling or embossing, allowing for the printing of brand logos or custom patterns to enhance brand recognition.

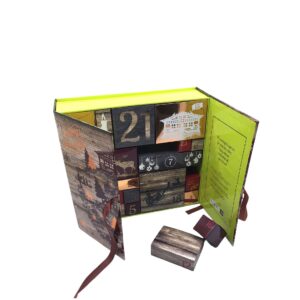

- Eco-Friendly Ribbon Pull Tab Functionality

- The top of the drawer integrates a biodegradable ribbon pull tab, making it easier to pull while preventing wear on the box, and simplifying the production process to reduce packaging assembly costs.

- The ribbon can be customised in colour and width, supporting FSC-certified eco-friendly materials, in line with green packaging trends.

4. Production and Certification Assurance

Rapid Prototyping and Quality Certification

- Leveraging years of packaging printing experience, physical samples can be provided within one hour, with support for 3D model previews and confirmation of physical details.

- Full production is certified by FSC Forest Certification, ISO 9001 Quality Management System, and BSCI Social Responsibility Audit, ensuring sustainability of raw materials and compliance in the production process.

5. Application Scenarios and Customer Value

- Retail Side: The drawer paper boxes design enhances shelf display attractiveness, with the orange hue stimulating consumer purchasing desire.

- Logistics Side: The compact box shape reduces transport damage rates to below 0.5%, with the inner lining’s shockproof performance passing ISTA 3A testing.

- Brand Side: Certification labels reinforce the company’s eco-friendly image, and the ribbon pull tab design balances functionality and aesthetics, suitable for high-end gift scenarios.