Abstract

In the fields of packaging design and home storage, drawer paper boxes and slider boxes have become core tools for enhancing user experience due to their modular design, efficient space utilisation, and personalised customisation capabilities. This article systematically elaborates on their structural characteristics, material innovations, application scenarios, and future trends, combining cutting-edge industry technologies, market data, and practical cases, providing a practical and forward-looking reference framework for consumers and businesses.

1. Definition and Core Structural Characteristics of Drawer Paper Boxes

Drawer paper boxes consist of an outer box and a slider box, inspired by the sliding mechanism of traditional matchboxes. Their core advantage lies in the dual-track nesting design: the outer box is formed from folded cardstock or hollow wall technology to create a stable frame, while the inner box achieves smooth extraction through guide rail grooves. For example, the stainless steel pull-out basket Drawer paper Boxes developed by Ningbo Deyili Kitchen uses a sliding rail system and modular shelf design, increasing vertical space utilisation by over 40%.

Modern high-end Drawer Paper Boxes also incorporate smart label management systems, such as detachable dividers and RFID tags in patented technologies, enabling item categorisation and quick retrieval. This structure is not only suitable for packaging but can also be expanded into wall-mounted storage systems, such as sliding lingerie boxes that adapt to different cabinet spaces through flexible combinations of rails and slots.

2. Materials and Craftsmanship: Technological Breakthroughs from Environmental Friendliness to Durability

1. Innovations in Eco-friendly Materials:

Biodegradable materials address traditional plastic pollution issues while extending lifespan through moisture-proof coatings. The combination of eco-friendly art paper and embossing technology balances aesthetics and sustainability.

2. High-Strength Composite Structures:

The use of double-layer folded outer walls enhances load-bearing capacity, while hollow wall boxes improve compression resistance through an annular edge design.

3. Design Advantages: Bidirectional Optimisation of Functionality and User Experience

1. Revolution in Space Efficiency:

The layered structure of drawer paper Boxes can increase storage density by 60%, as adjustable dividers in sorting boxes accommodate items of various sizes. The “one-button switch” design of slider boxes.

2. Upgraded Human-Computer Interaction:

Smart sensing drawers support remote control via smartphones, automatically popping up frequently used items. Child safety locks and rounded corner designs enhance safety.

4. Diverse Types to Meet Niche Market Demands

| Type | Features | Typical Applications |

|---|---|---|

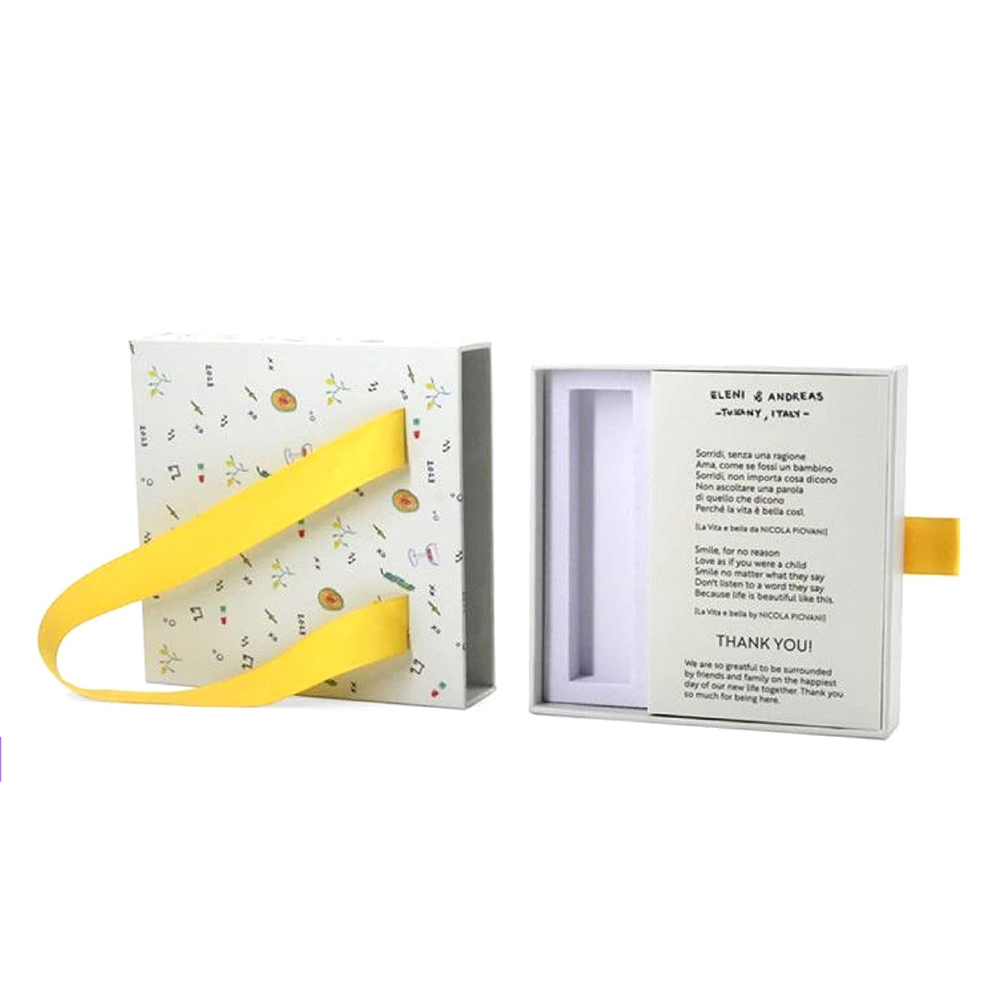

| Slider Boxes with Insert | Custom EVA linings secure fragile items, enhancing unboxing experience | Perfume sets, precision instruments |

| Openwork Wall-mounted Slider boxes | Double-sided pull-out structure, combining display and convenience | Retail displays, multilingual instruction packaging |

| Rolled-edge Closed Cardboard Boxes | Economical automatic assembly, suitable for mass production | Promotional vouchers, corporate brochures |

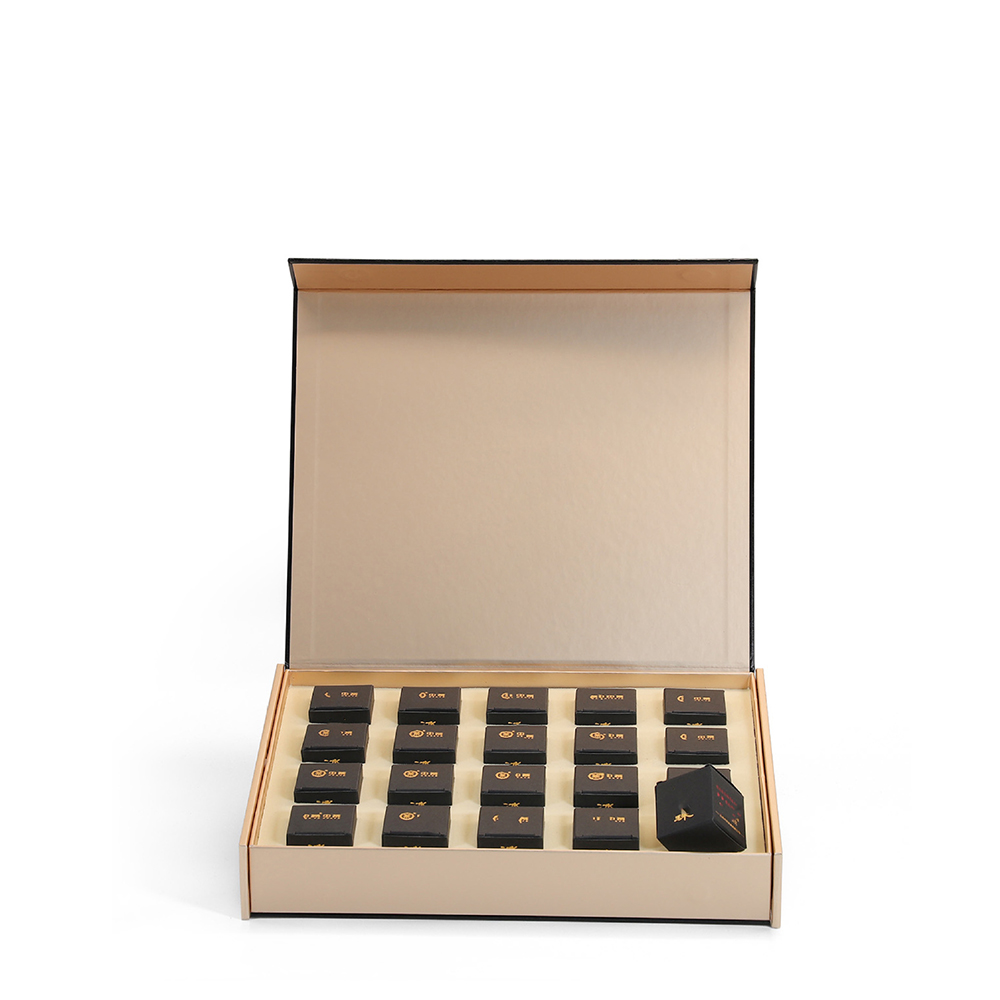

| Smart Divided Organising Boxes | Modular compartments + smart labels, supporting personalised combinations | Office stationery, medical equipment categorisation |

5. Cross-Industry Application Scenarios Analysis

1. Home Sector:

- Kitchen: Stainless steel pull-out drawer paper boxes achieve spice compartmentalisation and moisture management.

- Children’s Room: Fabric drawer paper boxes cultivate children’s habits of organised storage, with breathable materials to prevent mould growth.

2. Commercial Packaging:

- Luxury Goods: Bamboo slide curtain boxes enhance brand premium through artistic design.

- Electronic Products: drawer paper boxes with anti-static coatings protect delicate components, reducing transport loss rates.

3. Industrial Sector:

Tool drawer paper boxes improve workshop equipment management efficiency through impact-resistant PP material and magnetic fixation technology.

6. Customisation Trends: Extending from Functionality to Brand Value

1. Data-Driven Personalised Design:

Online platforms such as Baixiaohe support parametric modelling, automatically generating 3D renderings and die-cut diagrams after users input dimensions, with customisation cycles shortened to 72 hours.

2. Intelligent Integration:

Internet of Things technology enables drawer paper boxes to interact with smart home systems, for instance, a medication reminder function that pushes medication notifications in real-time via cloud functions.

3. Brand Narrative Medium:

Embossing techniques and gradient printing technology visualise brand stories, enhancing emotional connections with consumers.