Artificial Intelligence (AI) is reshaping the packaging industry at an unprecedented pace, with generative AI pushing the boundaries of creativity. However, this transformation extends far beyond visual innovation; machine learning is permeating the entire custom packaging ecosystem—from demand insights to recycling loops—resulting in revolutionary breakthroughs in efficiency and cost optimisation.

End-to-End Intelligence: The Reconstruction of the Custom Packaging Ecosystem

Traditional packaging processes suffer from significant information silos in design, production, and logistics. Today, AI has established a new ecosystem of data interconnectivity: intelligent consulting systems accurately align with customer needs, algorithm-driven optimisation enhances the synergy from design to procurement, and blockchain technology ensures supply chain transparency. Globally, 77% of packaging companies have adopted AI tools, with a quarter of the pioneers validating that ecosystem-level transformations can reduce material waste by 30% and shorten delivery times by 50%.

1. Demand Capture: From Passive Response to Predictive Creation

Intelligent customer service is no longer a simple Q&A machine. By analysing customer historical data and industry trends, AI can anticipate packaging needs that brands have yet to recognise—for example, recommending biodegradable glutinous rice paper packaging for emerging tea brands, aligning with environmental trends while addressing liquid leakage issues. Aptar Group’s AI model has achieved generating tailored solutions 48 hours before customer requests, improving conversion rates by 27%.

2. Creative Revolution: Algorithm-Driven Design Evolution

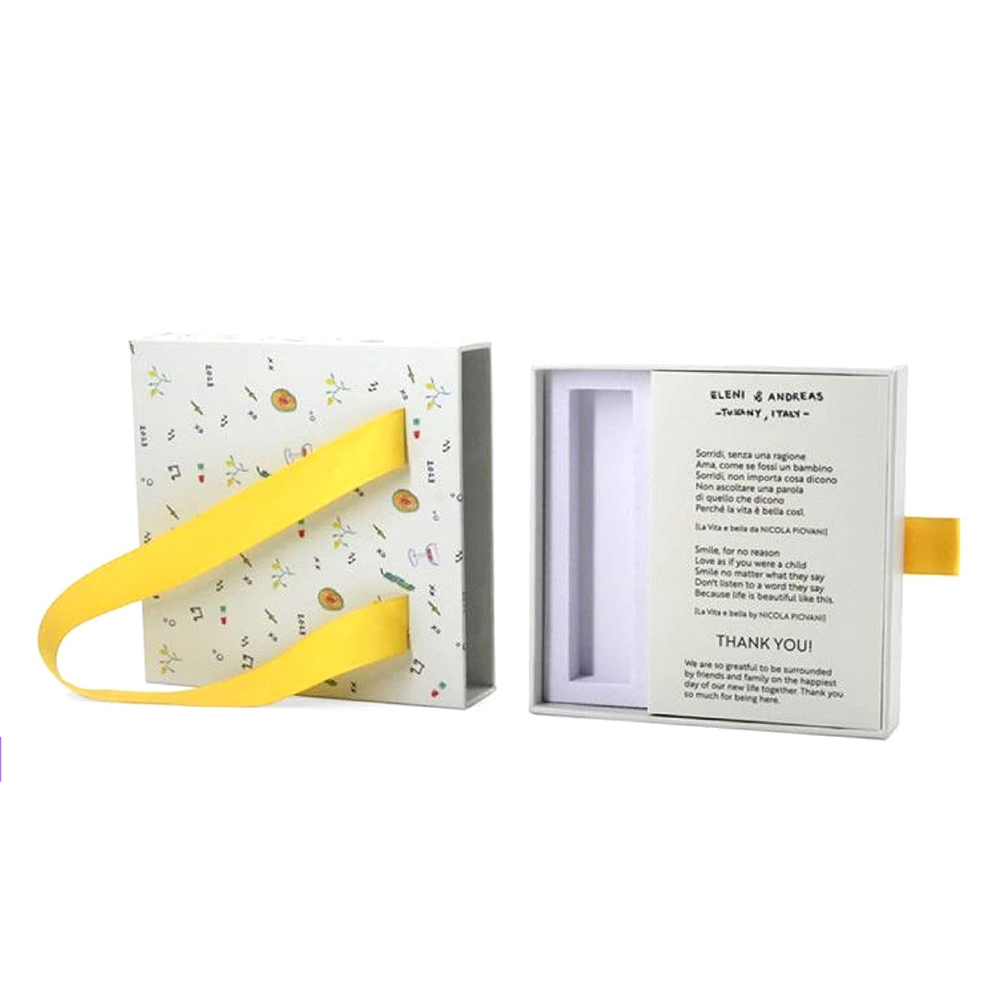

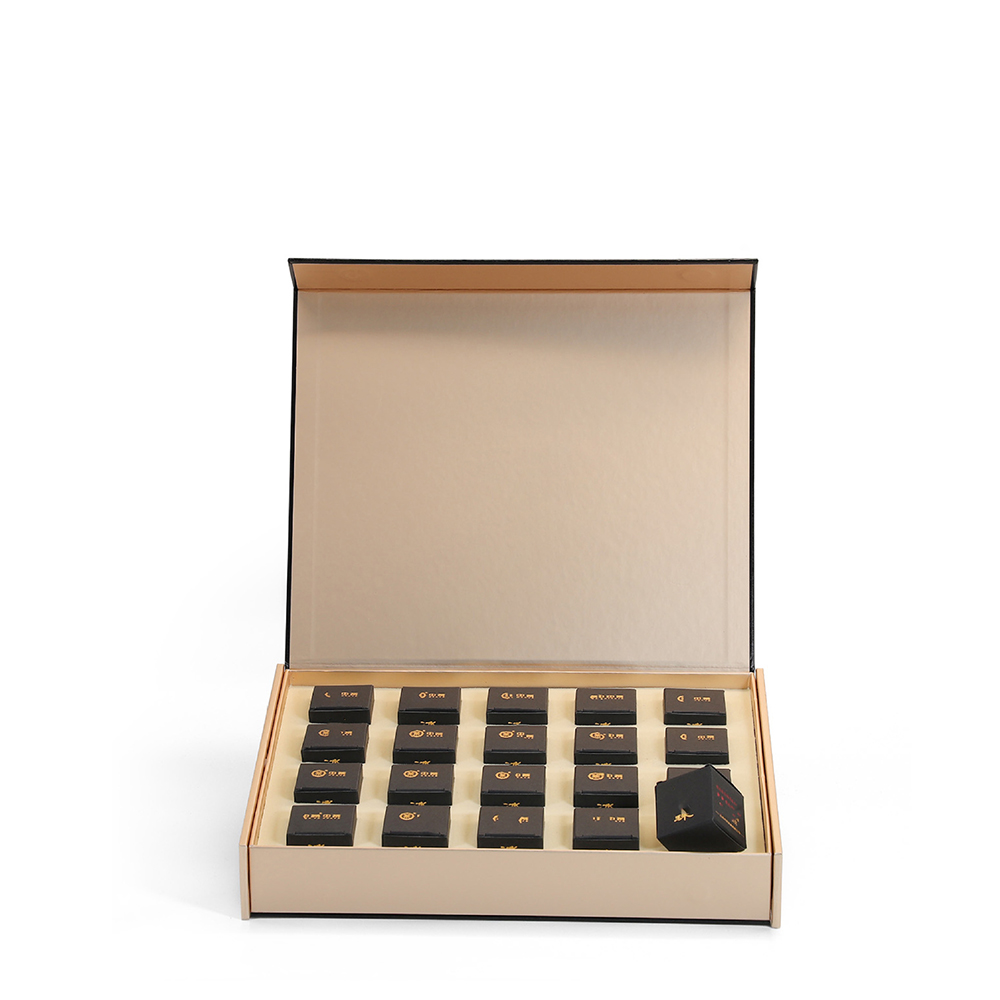

Tools like Midjourney are merely the starting point; Pacdora’s structural generation algorithm has realised “demand parameterisation”. By inputting product weight and transport scenario parameters, AI can simultaneously optimise cushioning structure design and visual aesthetics, enhancing protective performance by 40% while reducing material usage by 15%. L’Oréal’s latest perfume packaging has achieved a balance of glass thickness and translucency, maintaining a crystal-like quality while reducing transport damage rates to 0.3%.

Smart Manufacturing Loops: Intelligent Transition from Factory to Shelf

1. Simulated Iteration: Thousands of Virtual Validations Replace Physical Loss

AI prototype systems are rewriting the rules of the game. Unilever utilises a virtual drop testing platform capable of completing 3,000 transport environment simulations in a single day, accurately pinpointing vulnerable areas. Compared to traditional methods, the development cycle has been compressed from 8 weeks to 72 hours, with material loss reduced by 82%. More advanced VR shelf simulation technology allows packaging to gather consumer visual engagement data before market launch, achieving an 89% accuracy rate in shelf competitiveness predictions.

2. Green Manufacturing: AI-Driven Circular Economy

In the materials procurement phase, AI not only compares prices but also builds environmental assessment models. Henkel’s intelligent procurement system can simultaneously analyse the degradation cycles, carbon footprints, and cost curves of 120 types of bio-based materials, resulting in an 18% cost reduction for eco-friendly packaging solutions. On the recycling front, sorting robots equipped with spectral recognition AI boast an impressive 99.7% accuracy in identifying deformed or soiled packaging, allowing PET recycling purity to exceed food-grade standards.

Ecological Challenges: The Double-Edged Sword of Intelligent Reform

As AI design tools generate over 100,000 solutions daily, the boundaries of copyright grow increasingly blurred. A certain emerging brand’s AI-generated “Ukiyo-e style” packaging has sparked litigation due to the algorithm’s training data involving multiple artists, exposing the lag of the current intellectual property system. More critically, the advancement of smart factories poses a 38% job restructuring challenge for Southeast Asian packaging companies, compelling the industry to establish a skills integration system between AI engineers and traditional technicians.

The Future is Here: A New Era of Intelligent Custom Packaging

From Amazon’s drone delivery AI obstacle avoidance algorithms to intelligent packaging chips that sense inventory, custom packaging is evolving into a “thinking” ecosystem. Companies that have been early adopters of AI ecosystems have already gained a competitive edge—industry data indicates that end-to-end intelligent transformations have increased customer retention rates by 41% for leading companies, with overall packaging costs per unit decreasing by 24%.

This revolution transcends mere technological replacement; it constructs a new ecosystem of human-machine collaboration. When AI manages 90% of standardised processes, human designers can focus on emotional design; as algorithms optimise supply chains, managers can concentrate on strategic innovation. The future landscape of the packaging industry is clear: intelligence is not the endpoint but rather an essential pathway towards personalisation and sustainability.