Abstract

With the increasing consumer market demand for brand differentiation and environmental sustainability, custom food packaging boxes have become a key vehicle for food enterprises to enhance competitiveness and convey brand value. This article systematically analyses how to create food packaging solutions that are both attractive and practical from eight core dimensions, including design strategy, material selection, functional innovation, and regulatory compliance. It also explores industry trends and implementation paths for eco-friendly packaging boxes, providing food enterprises with a one-stop customisation guide.

1. Custom Design Strategy Focused on Consumer Insights

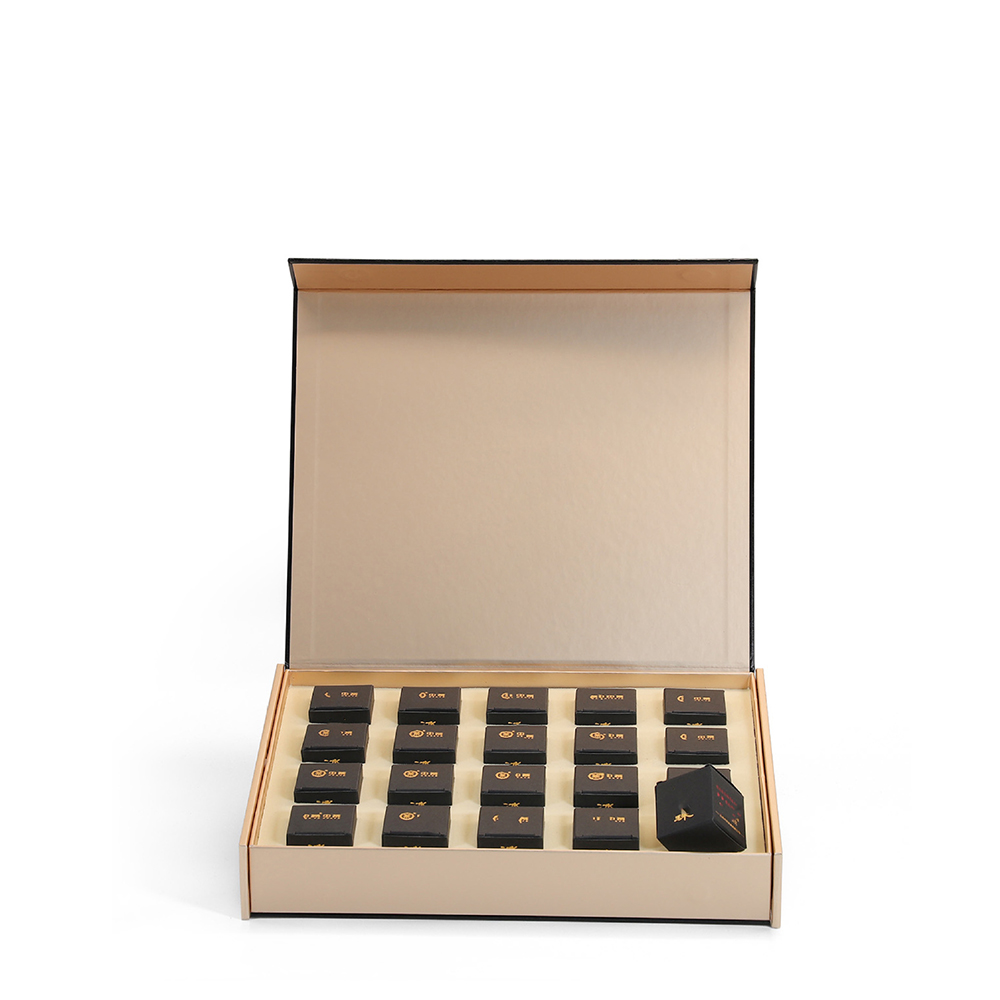

1. IP Collaborations and Thematic Design

Integrating popular cartoon characters or festive elements (such as Christmas trees or Valentine’s heart-shaped boxes) can effectively reach target demographics. Research indicates that children’s purchase intent for anime IP packaging increases by 37%, while festive-themed packaging can boost seasonal sales by 52%. For instance, Disney-branded chocolate boxes achieved a 30% premium sales performance through IP licensing.

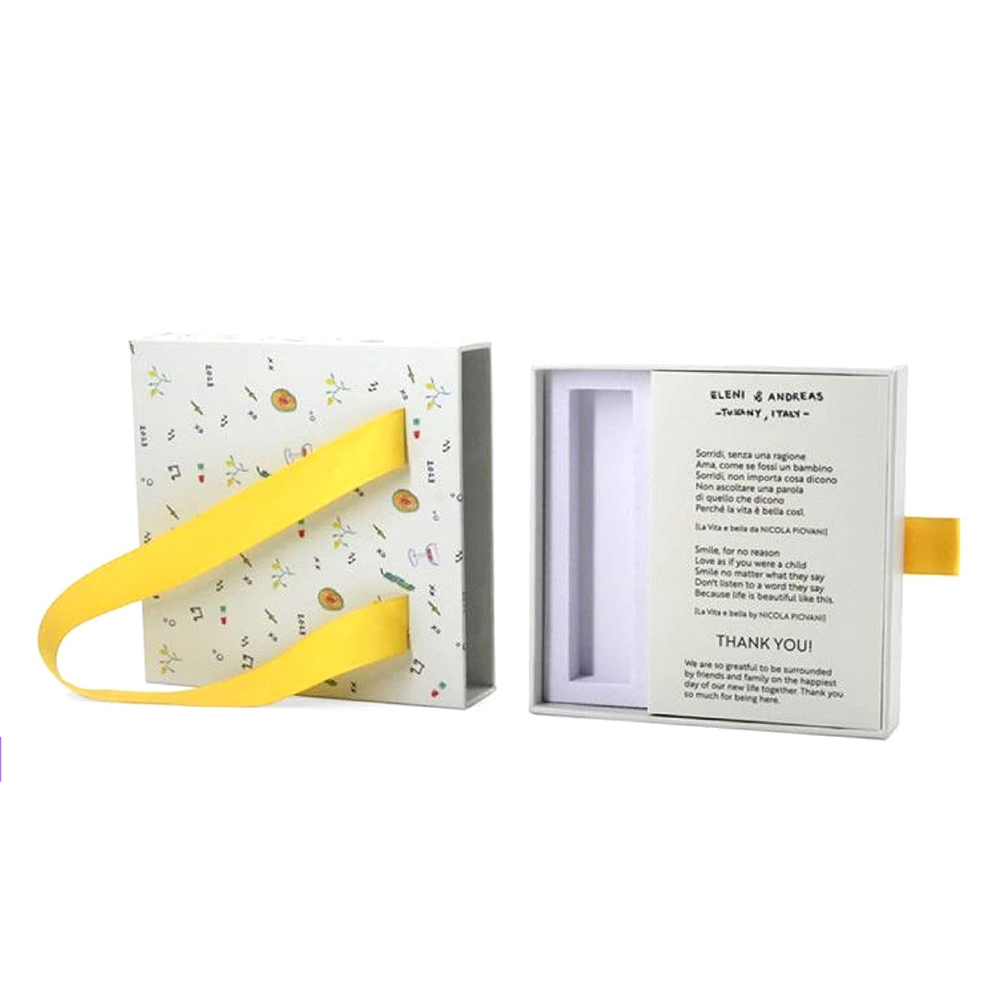

2. Visualisation of Brand Narrative

Packaging boxes should embody brand DNA, reinforcing memory through three-dimensional gold foil logos, a brand colour ratio of over 60%, and creative slogan layouts. Studies show that packaging with a unified visual system can enhance brand recognition by 2.3 times; for example, Godiva’s use of a gold embossed logo increased repurchase rates by 19%.

2. Balancing Science and Art in Material Selection

1. Food-Grade Safety Material Standards

• Paper materials: Prioritise the use of FSC-certified food-grade materials, with the inner layer conforming to GB 9685 standards for food contact materials, and prohibit fluorescent whitening agents.

2. Advanced Solutions for Eco-Friendly Packaging Boxes

Utilising bagasse-based biodegradable materials (degradation period ≤ 180 days) or PLA corn starch composite materials can reduce carbon emissions by 67% compared to traditional plastics. Data indicates that the biodegradable packaging market will reach $12 billion by 2024, with a compound annual growth rate of 18%.

3. Functional Innovations Enhancing Consumer Experience

1. Preservation Technology and Structural Design

Extending shelf life through designs such as foil composite layers (oxygen barrier rate ≥ 99.5%) and moisture-absorbing slots. Barrier packaging can extend the shelf life of nut products by 40%. For example, Meiji chocolate from Japan employs nitrogen filling and one-way breathable valve design, reducing oxidation rates by 58%.

2. Integration of Smart Interaction

Embedding NFC chips for QR code traceability and temperature-sensitive inks to monitor cold chain status. Case studies show that smart packaging reduces fresh food loss rates by 29%; for instance, Oatly oat milk uses QR codes to display carbon footprint data, resulting in a 23% conversion rate increase.

Summary

Custom food packaging boxes have evolved from mere containers into strategic brand tools. Enterprises must balance aesthetic expression, functional innovation, and sustainable development in design. By selecting eco-friendly packaging materials based on precise consumer insights and integrating smart technologies to optimise consumer experience, while strictly adhering to regulatory guidelines to control compliance risks. In the future, as the cost of biodegradable materials decreases by 25% and AR packaging technology becomes widespread, food packaging will become a core touchpoint for establishing emotional connections between brands and consumers.