The first touchpoint consumer is with a brand and the main vehicle to express the product price. When selecting between stock packaging and custom packaging, businesses should take extensive decisions that consider brand positioning, cost budget and market demand. This article will be engrossed in the differences and applicable scenarios of both, introducing innovative practices in brand packaging boxes and custom packaging solutions to provide references for enterprises in different stages of development.

1. Stock Packaging: A Low-Cost and Efficient Choice

Stock packaging includes pre-made standard products that use universal shapes, materials and designs, such as general corrugated boxes and food cans. Its main benefits are contained in quick delivery and low cost: there is no need for custom molds, allowing suppliers to produce and supply immediately. For startups or short-term marketing activities (such as exhibition samples or subscription mystery boxes), stock packaging can quickly meet basic needs, especially suitable for scenarios with limited budgets or those testing market reactions.

However, the limitations of stock packaging are significant:

- Weak Brand Recognition: It relies on stickers or labels for secondary processing, lacking visual appeal and struggling to establish a premium image;

- Poor Adaptability: Standard sizes may cause products to shift, requiring filler materials like shredded paper or bubble wrap for protection, which increases material waste;

- Environmental Shortcomings: Traditional stock packaging often uses non-biodegradable materials, which do not align with green consumption trends.

2. Custom Packaging: An Amplifier of Brand Value and User Experience

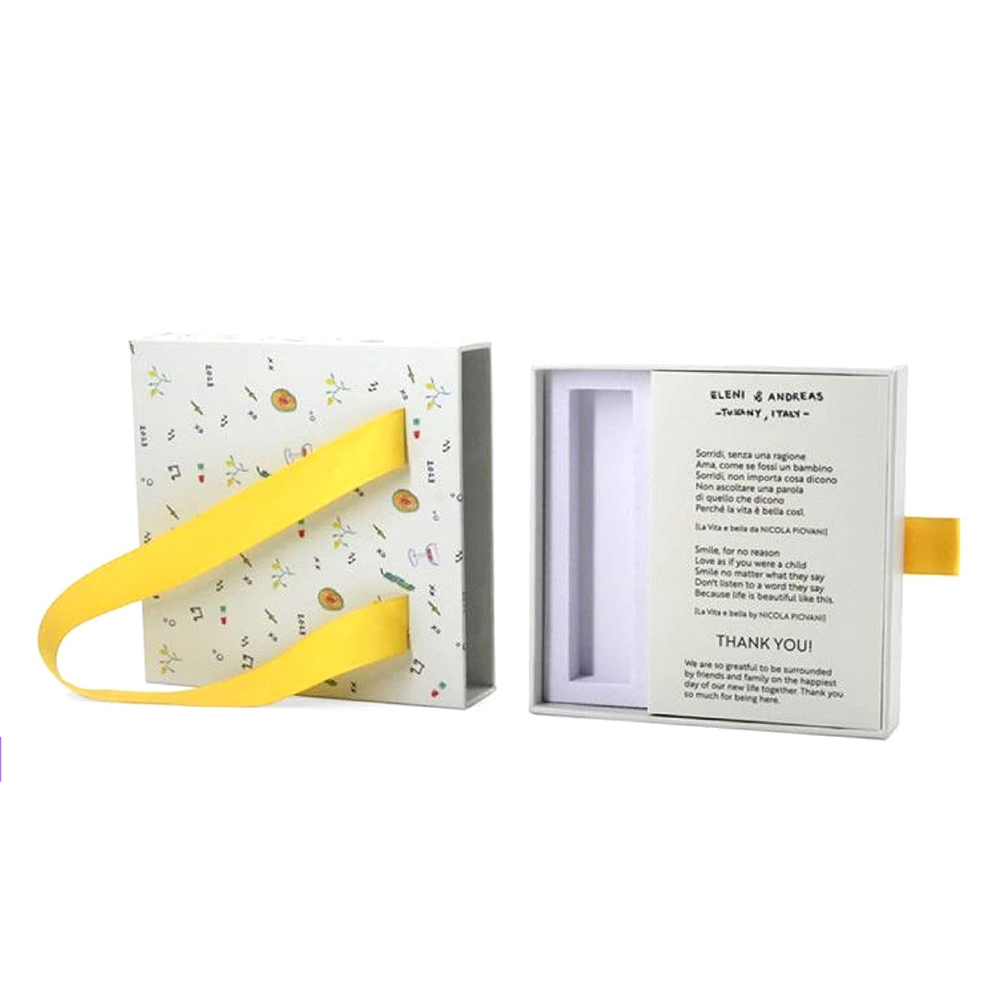

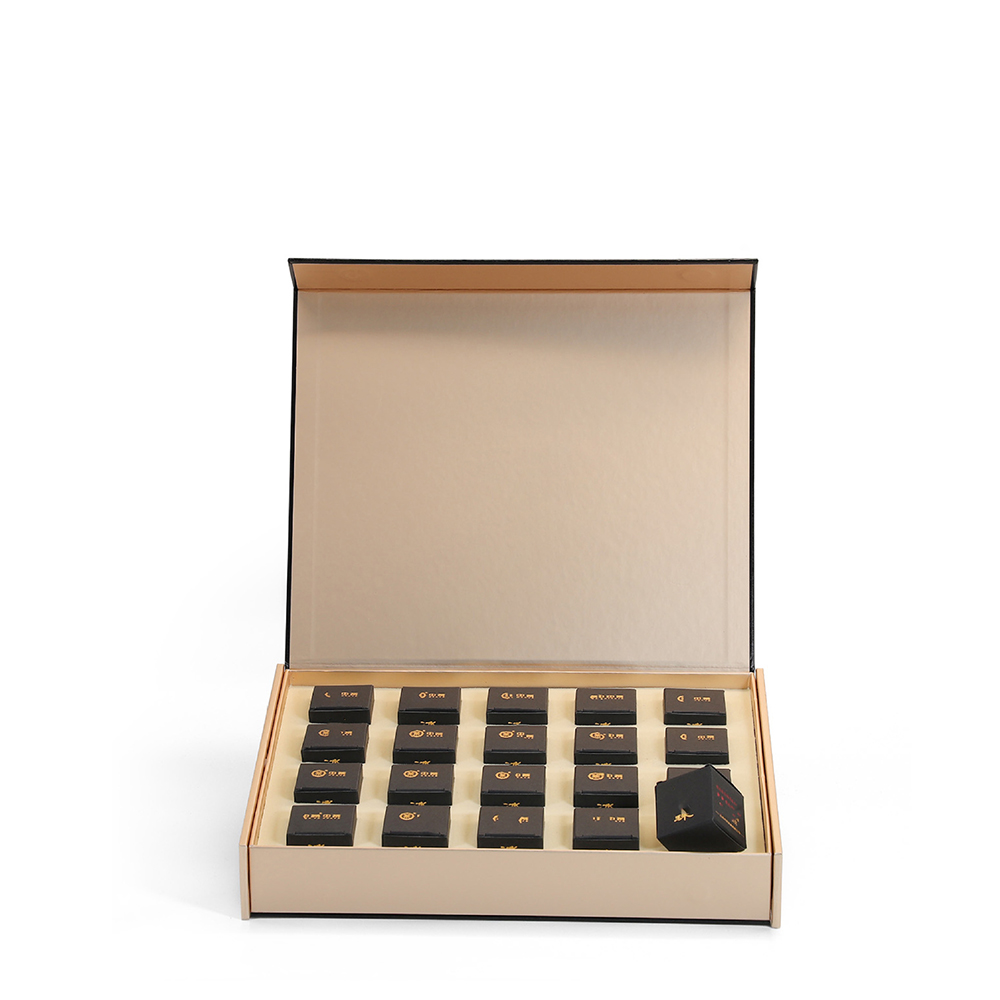

Unlike stock packaging, custom packaging solutions achieve a deep connection between products and brands through exclusive designs. For example, luxury brands often use silk linings and acrylic layered gift box structures to transform the unboxing experience into a brand ritual. Its core advantages are reflected in three areas:

1. Precise Matching of Product Needs

Custom packaging can be designed with functional structures based on product characteristics:

- Fragile Items: A combination of shock-absorbing foam and reinforced corrugated layers increases load-bearing capacity by 50%;

- Fresh Foods: Waterproof films and resealable bags reduce waste rates from 8% to 1.2%;

- Electronic Products: Lightweight heavy-duty boxes balance protection and transport costs.

2. Enhanced Brand Awareness

Through techniques such as gold foil stamping, embossing, or AR smart packaging, businesses can integrate visual identity elements into every detail. For instance, a jewellery brand increased its repurchase rate by 30% through custom packaging, while the interactive features of smart packaging can boost conversion rates by 27%.

3. Trends in Sustainability and Technology

Custom packaging is evolving towards environmentally friendly and technological solutions:

- Recyclable Materials: For example, the combination of plastic pallets and anti-static EU boxes from the RRS supply chain reduces packaging costs by 20%;

- Smart Monitoring: Using RFID chips or temperature control sensors allows for comprehensive tracking throughout the transportation process.

3. Decision-Making Guide: Four Steps to Identify the Optimal Solution

1. Assess Brand Stage:

Startups may prioritise stock packaging with custom labels as a transition; established brands need to reinforce a premium image through custom packaging.

2. Calculate Costs and Order Volumes:

Custom packaging requires meeting the MOQ (minimum order quantity) to amortise mould costs, while stock packaging supports small batch purchases.

3. Analyse Product Characteristics:

Irregular products (such as medical devices) must be custom-made; standard products can initially use stock packaging.

4. Focus on Long-Term Value:

Although custom packaging has higher initial investments, it can enhance ROI through brand premium and customer loyalty.

4. Future Trends: Cross-Industry Integration of Custom Packaging Solutions

With technological advancements, custom packaging has transcended the functionality of a single container, extending towards full-chain services:

- Data-Driven Marketing: Packaging embedded with NFC chips allows consumers to scan and participate in promotional activities, enabling businesses to simultaneously gather user behaviour data;

- Sustainable Closed Loops: Initiatives like trade-in recycling programmes promote the circular use of packaging materials;

- Scenario-Based Design: Wedding gift boxes incorporating AR dynamic effects and food packaging featuring braille labels cater to the needs of niche audiences. Conclusion Inventory packaging and customised packaging are not opposing options, but rather a strategic combination for businesses at different stages of development. Through the refined design of brand packaging boxes and the innovative application of customised packaging solutions, companies can control short-term costs while also accumulating long-term brand equity. In a market dominated by green consumption and personalised demands, only by viewing packaging as a strategic investment can one maintain a competitive edge.