Abstract

In the context of the global trend of low carbon economy and green consumption, selection of packaging box has shifted a unique focus on functional requirements, transferring environmental friendship, economic feasibility and widespread idea of market adaptability. This article systematically analyzes scientific selection strategies for packaging materials through five main dimensions-product compatibility, market status, protective performance, economic and environmental stability, and security-when explaining the innovative applications of biodegradable content and cost-affected eco-friendly packaging, which provides business to balance business value and social responsibility.

1. Product Compatibility: Precise Matching from Physical Characteristics to Functional Requirements

The selection of packaging materials must prioritise product characteristics. For example:

- Liquid Products (such as cosmetics) require highly sealable materials, such as PET plastic or aluminium-plastic composite films, to prevent leakage and oxidation;

- Fragile Items (glass products) should be paired with honeycomb cardboard or pearl cotton cushioning structures, which enhance impact resistance by over 40% compared to traditional foam plastics;

- Food Products must comply with FDA-certified biodegradable materials, which can block microorganisms while avoiding chemical migration risks.

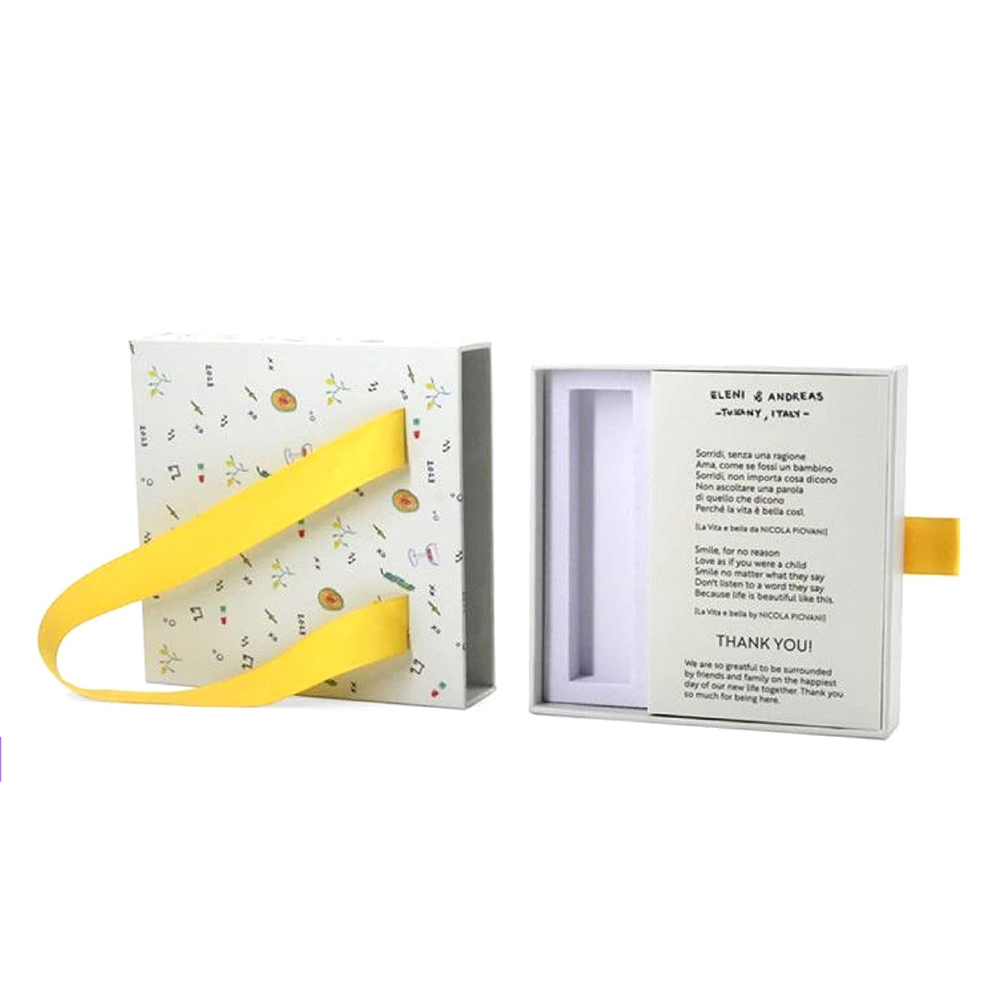

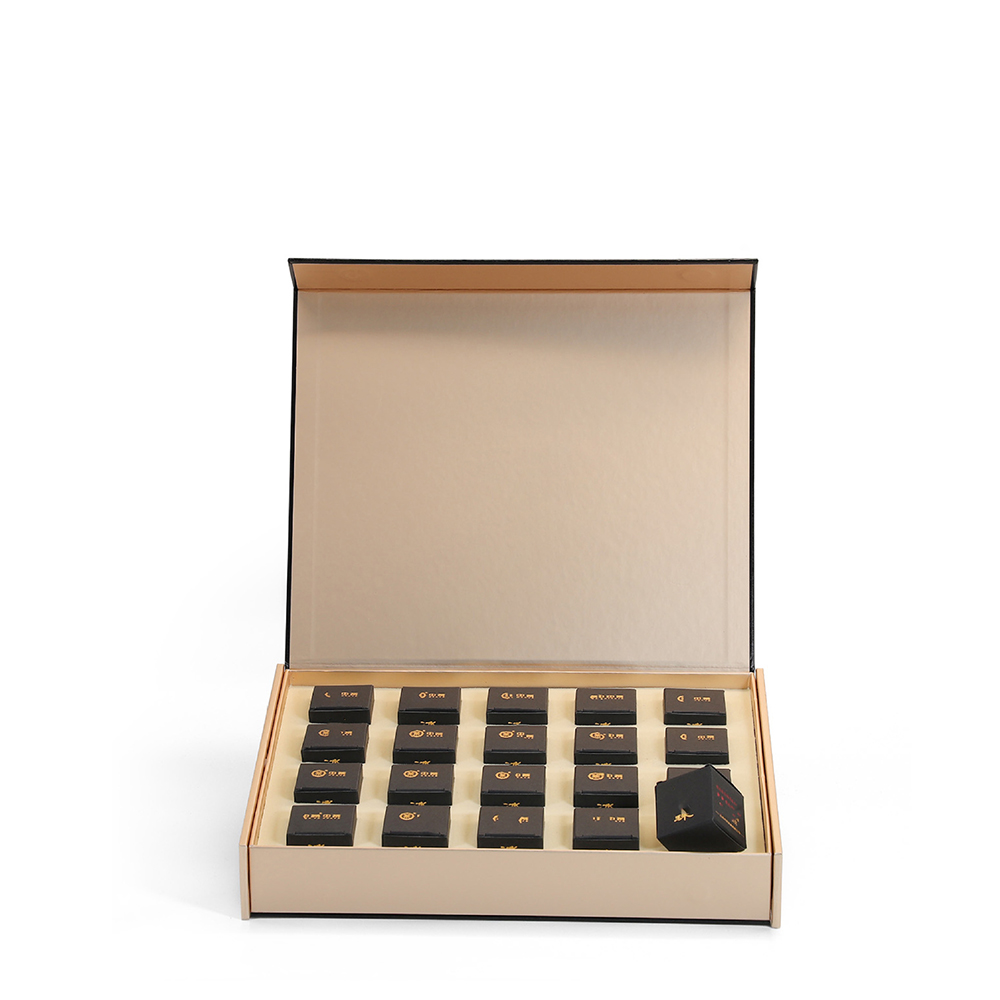

2. Market Positioning: Collaborative Design of Consumer Psychology and Brand Value

Packaging serves as a silent advertisement for brands and must deeply resonate with the needs of the target audience:

- High-End Market: Utilise laser-printed card stock combined with gold foil techniques to enhance quality perception. The LV perfume range uses FSC-certified recycled wood packaging, increasing its premium capability by 30%;

- Mid-Range Market: Recommend lightweight soy ink printing, which is environmentally friendly and pollution-free;

- Mass Market: Opt for recyclable kraft paper or high-quality coated paper materials to meet cost-performance demands.

Data: According to research, 72% of consumers are willing to pay a 5%-10% premium for eco-friendly packaging, while high-end brands have seen customer conversion rates increase by 28% through sustainable packaging.

3. Protective Performance: Comprehensive Protection from Structural Mechanics to Environmental Barriers

The protective capability of packaging directly affects product loss rates and customer satisfaction:

- Mechanical Strength: Heavy industrial equipment requires steel-wood composite boxes, capable of bearing up to 500kg/m²;

- Environmental Barrier: Pharmaceutical packaging must use aluminium foil composite films, with water vapour transmission rates ≤0.5g/m²·24h, ensuring the stability of drug shelf life;

- Smart Monitoring: The application of RFID tags and temperature control sensors can monitor the status of fresh cold chain packaging in real-time, reducing loss rates to below 3%.

4. Economic and Environmental Sustainability: Balancing Cost Control with Ecological Benefits

The core of sustainable packaging lies in optimising the total lifecycle costs:

- Biodegradable Materials:

- PLA: Degradation period of 6-12 months, with a unit price 25% higher than traditional plastics, but government subsidies can cover 30% of the costs (EU EN 13432 certified);

- Moulded Pulp: Take-out boxes made from sugarcane bagasse, with costs reduced to 0.8 yuan each after mass production, saving 40% in logistics space compared to EPS foam.

- Circular Economy Model:

- SF Express’s “Feng BOX” reusable delivery box, usable over 50 times, reduces single-use costs by 60% compared to cardboard boxes;

- IKEA’s global furniture rental service, using modular steel-wood packaging, has improved material recovery rates to 95%.

5. Safety: Rigorous Standards from Chemical Inertness to Health Compliance

The safety of packaging materials directly impacts consumer trust and legal compliance:

- Non-Toxic Certification: Food contact-grade materials must pass GB 4806.1-2016 testing, with heavy metal migration levels below 0.01mg/kg;

- Environmental Certification: FSC forest certification, OK Compost industrial composting marks, etc., enhance international market access capabilities (such as EU RoHS directives);

- Antibacterial Technology: Medical packaging with silver ion coatings can inhibit 99.9% of bacterial growth, already applied in Johnson & Johnson surgical instrument sterilisation packaging.

Summary

The selection of sustainable packaging is a key aspect of a company’s implementation of ESG strategies. By accurately matching product requirements, designing market positioning in layers, enhancing protective performance, optimising economic and environmental indicators, and strictly adhering to safety standards, companies can build differentiated green competitiveness. In the future, with breakthroughs in bio-based material technologies (such as mycelium packaging and seaweed-based films) and increased policy incentives, the packaging industry will accelerate its progress towards the “zero waste” goal. Taking immediate action and choosing scientifically sustainable packaging solutions not only reduces supply chain costs but also wins consumer trust and policy benefits, achieving dual growth in commercial value and social benefits.