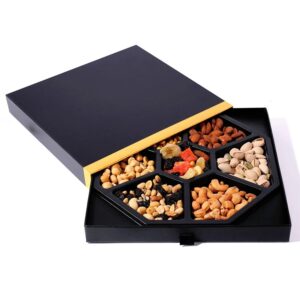

Luxury Cardboard Magnetic Closure Seal Rigid Box for Food

The magnetic closure box structure is adopted, the box body opens and closes smoothly, is strong in stability, and the edges fit tightly after closing, which is both practical and ceremonial. It is combined with a gift bag of the same color to form a set to meet the needs of different scenarios (such as holiday gifts, brand activities), and is suitable for business, light luxury and other fields. The hot stamping process has high color saturation, is wear-resistant and does not fade, highlighting the exquisiteness of the brand.

Description

Luxury Cardboard Magnetic Seal Food Box Product Description

1. Magnetic Sealing System: A Precise Balance of Technology and Aesthetics

- Precision Magnetic Closure: Utilises a neodymium-iron-boron permanent magnet array design, achieving a secure closure with an adhesion force of ≥5N. The opening and closing process provides a clear “click” tactile feedback, ensuring a tight seal that effectively prevents air and moisture ingress.

2. Scenario-based Set Design: From Single Packaging to Brand Experience System

- Business Gift Solution: The main box body is paired with a matching gold-foiled gift bag, offering flexible configurations from single boxes to combination sets (e.g., 2/4/6-piece sets). The gift bag is made from 250g white card with a matte lamination process, featuring a non-slip silicone strip in the handle, suitable for business gifts, VIP client appreciation, and other scenarios.

- Cross-industry Compatibility: The deep blue primary colour is paired with optional champagne gold/platinum grey, achieving 99% colour reproduction through Pantone spot printing. The finance industry can opt for foil-stamped currency patterns, technology brands can customise circuit board etching textures, and the beauty sector can adapt rose gold embossed logos.

3. Sustainable Material System: The Coexistence of Environmental Protection and Luxury

- FSC Forest Certification: Paper-based materials are 100% certified by FSC-COC for production and sales supervision, with raw materials sourced from sustainably managed forests in Northern Europe. The lining is made from food-grade sugarcane residue moulded to form, with a natural degradation rate of 92%.

- Green Production Process: The ink system is certified by EU REACH, and the gold foiling process employs low-temperature cold foiling technology, reducing energy consumption by 40% compared to traditional methods.

4. Visual Communication System: Gold Stamp Foil Technology Reshaping Brand Recognition

- Micron-level Foil Printing Precision: Utilises German Kurz electroplated aluminium foil, with a gold layer thickness of 12μm, passing wear tests of 5000 cycles without flaking. Supports six special effect processes, including three-dimensional embossing and holographic laser, with the smallest foil printed text reaching 0.8mm.

- Dynamic Light and Shadow Design: The deep blue substrate undergoes five coatings to achieve a mirror effect, complemented by 22° angled gold foil lines, presenting a flowing metallic texture under different lighting conditions.

5. Full-Chain Service Support: Hassle-free Delivery from Concept to Implementation

- Design Optimisation Module: Provides 3D structural simulation testing, delivering weight-bearing, stacking, and transportation scenario simulation reports within 72 hours.

- Cost Control System: Reduces the amount of magnetic material used per unit by 15% through a circular array arrangement of magnets, combined with a flexible production system to achieve a minimum order quantity of 500, lowering sampling costs by 60% compared to traditional packaging.