Luxury Cosmetic Beauty Packaging Top and Bottom Box Company

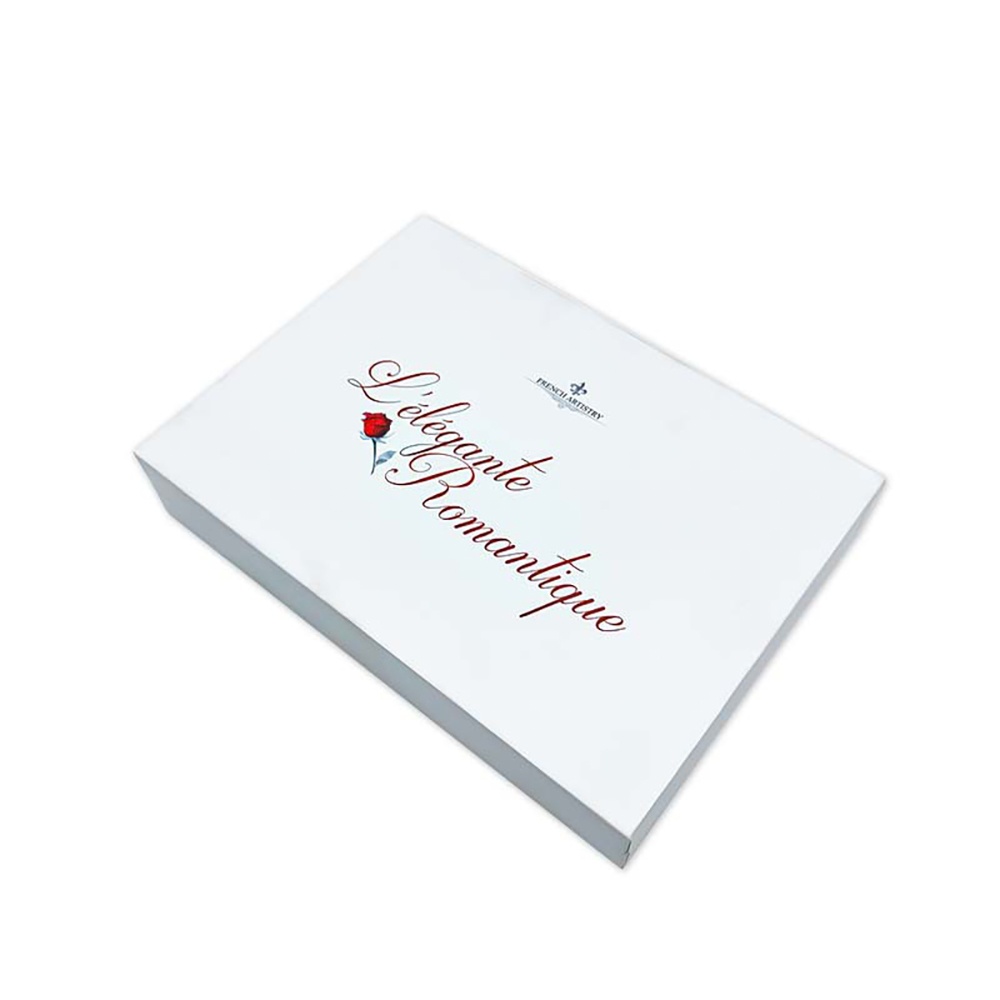

The top and bottom box cover structure realizes an integrated opening and closing experience. The lid and the box body are precisely nested without gaps. The opening and closing are smooth and the closing is stable. The box line is simple and neat, without redundant decoration, which is suitable for the packaging needs of high-quality products such as luxury goods and beauty products.

Description

Brand High-End Customised Lid and Base Gift Box Product Description

1. Structural Design: Integrated Lid and Base for Precision and Stability

Utilising an advanced optimisation scheme for the lid and base box type, the box lid and base are formed through precision moulding, achieving seamless nested closure.

- Precise Nesting: The box body edge tolerance is controlled within ±0.2mm, ensuring a tight fit upon closure to prevent dust ingress during transport; the opening and closing mechanism is optimised through mechanical simulation, allowing for smooth one-handed operation, while remaining stable and pressure-resistant when closed.

- Reinforced Load-Bearing: The box base is made from 1200g rigid grey board, complemented by an internal honeycomb structure, allowing a single box to bear up to 5kg, maintaining its shape when stacked up to 10 layers, meeting storage, transport, and retail display requirements.

- Applicable Scenarios: Suitable for high-value beauty products such as bottles, powders, and serums, the box design features minimalist and fluid lines with no superfluous decorations, aligning with the luxury philosophy of “less is more”.

2. Visual Design: Rose Motif Embodying Luxurious Ritual

The core design language centres around a rose pattern, blending brand tone and product characteristics:

- Pattern Design: The rose lines utilise vector micro-engraving technology, with clear petal veins, paired with a hot stamping technique in red gold, presenting a luxurious texture of flowing light and shadow.

- Unboxing Ritual: At the moment the box lid opens, the internal padding and rose pattern create a visual extension, resembling petals blooming layer by layer, enhancing the experience of “luxury from the moment of unboxing”.

- Colour Control: The red and gold colour scheme is calibrated with Pantone spot colours, ensuring colour difference in mass production is ≤5%, maintaining colour saturation and recognisability even under bright light.

3. Service Advantages: Agile Development and Quality Verification

- 1-Hour Sample Production: Leveraging a digital sampling system, providing high-definition 3D renderings and physical samples delivered simultaneously for quick design feasibility validation.

- 3-Hour Craft Verification: Through laboratory-level testing (including drop, temperature and humidity, and compression tests), real-time feedback on material and craft combination data ensures consistency in mass production.

- Customisation Response: Supports personalised accessories such as logo hot stamping, magnetic clasps, and ribbons, with proposal iterations completed within 48 hours.

4. Application Scenarios and Market Feedback

- Applicable Fields: High-end skincare gift boxes (such as serums, creams), limited edition makeup sets, luxury gift packaging, etc.

- Client Case Study: After adopting this scheme, an international beauty brand reported a 40% increase in customer satisfaction regarding the unboxing experience, with transport damage rates reduced to 0.3%.