Luxury Two Sides Open Cosmetic Packaging Paper Box Makers

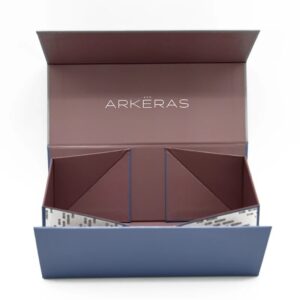

The double side open gift box achieves a balance between symmetrical aesthetics and practicality. The dark brown door panel on the outside and the light beige inner wall on the inside form a color contrast, creating an immersive experience of “surprise upon opening the box”. The FSC-certified raw materials confirm its forest-friendly attributes, which is in line with the environmental protection trend of luxury packaging.

Description

Luxury Two Sides Open Cosmetic Packaging Paper Box Makers Product Description

1. Symmetrical Double-Opening Box: A Dual Innovation of Aesthetics and Functionality

Featuring a double-opening structure with a top and bottom lid, the left and right door panels are connected by precision hinges, allowing for an opening angle of 180°, creating a symmetrical aesthetic ritual at the moment of unboxing. The interior of the box is equipped with a sliding inner box framework, combined with a magnetic clasp design to ensure a snug fit when closed, while also supporting one-handed opening and closing, balancing high-end visuals with practical convenience. The box dimensions are ergonomically optimised to suit standard shelf displays and gifting scenarios, enhancing the attractiveness of terminal displays.

2. Colour Collision: Sensory Narrative of Dark Brown and Light Beige

- External Design: The door panels are made from dark brown matte DuPont paper, with the brand logo and scroll patterns embossed on the surface, providing a warm and durable touch that conveys the classic luxury brand gene.

- Internal Design: The inner walls utilise light beige FSC-certified cotton paper, enhancing the visual impact of unboxing through colour temperature contrast, paired with a glossy laminated lining to reflect light and create an immersive “jewellery display” atmosphere.

3. Eco-Friendly Core: FSC Certification and Zero Plasticisation Process

- Raw Materials: The main material of the box is certified by the FSC Forest Stewardship Council, ensuring traceability of bamboo fibre and recycled paper pulp, aligning with ESG standards in the luxury goods industry.

- Process Upgrade: A water-based eco-friendly coating replaces traditional lamination, achieving waterproof and moisture-proof functions while avoiding microplastic pollution, with a degradation cycle shortened to within 6 months.

4. Precision Shock-Absorption System: Collaborative Protection of Die-Cutting Technology and High-Elastic Foam

- Die-Cutting Technology: Based on AI die-cutting database, the sponge slot parameters achieve laser cutting precision of ±0.1mm, accommodating the fixed needs of irregular perfume bottles and accessories, with shock resistance tested to ISTA 3A international standards.

- High-Elastic Foam: Utilising polyurethane memory foam, with a density of ≥45kg/m³ and a rebound rate exceeding 90%, it offers customisable partition structures compatible with the protection of perfume bottles, jewellery, precision instruments, and more.

5. Intelligent Production: Rapid Moulding in 1 Hour and Fully Digitalised Process

- Intelligent Die-Cutting Library: Integrating 3000+ die-cut models, supporting automatic matching with CAD drawings, reducing manual adjustment time.

- Rapid Moulding System: Leveraging industrial-grade 3D printing and CNC precision carving, the entire process from design draft to physical sample is completed within 1 hour, accelerating product iteration and validation.

6. Application Scenarios and Derivative Value

- Luxury Goods Sector: Can be paired with hot-stamped belly bands or gemstone inlays to enhance the collectible value of the gift box.

- Brand Promotion: Supports the embedding of NFC chips or AR interactive tags, linking digital brand stories to enhance consumer engagement.