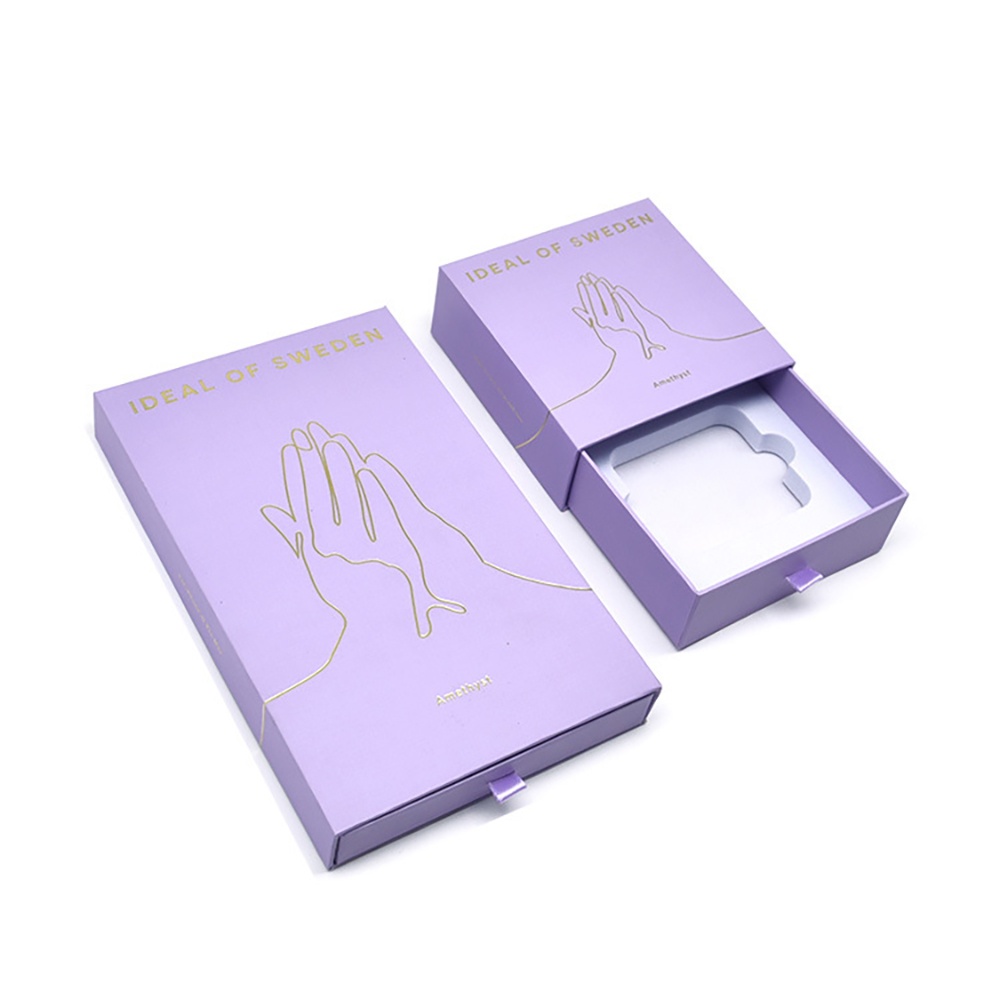

Makers Bespoke Match Slide Style Rigid Box for Cosmetic

The paper drawer box opening and closing structure reduces the resistance when opening the box and strengthens consumers’ memory of the packaging function. The groove lining accurately matches the depth of the box body, reducing the risk of transportation loss. It is very suitable for your cosmetic packaging box.

Description

Makers Custom Sliding Rail Cosmetic Hard Box Product Description

1. Innovative Structural Design: Merging Precision Mechanics with Sensory Experience

- Sliding Rail Pull-Open Structure

- Utilises a high-precision sliding rail system, with a pull resistance coefficient as low as 0.3N, ensuring a silky smooth opening and closing process that completely eliminates the jarring sensation of traditional packaging.

- The sliding rail is equipped with 304 stainless steel ball bearings, showing no deformation after 3000 pull tests, enhancing durability by 200% and reinforcing the consumer’s memory of the “pull to open” feature.

- Deeply Matched Groove Lining

- Custom groove lining created through 3D laser scanning technology, with depth deviation controlled within ±0.5mm, ensuring zero displacement for bottles, jars, and irregular brushes.

- Combined with EVA cushioning material, achieving an anti-shock coefficient of level 8, reducing transport loss rates to 0.3%.

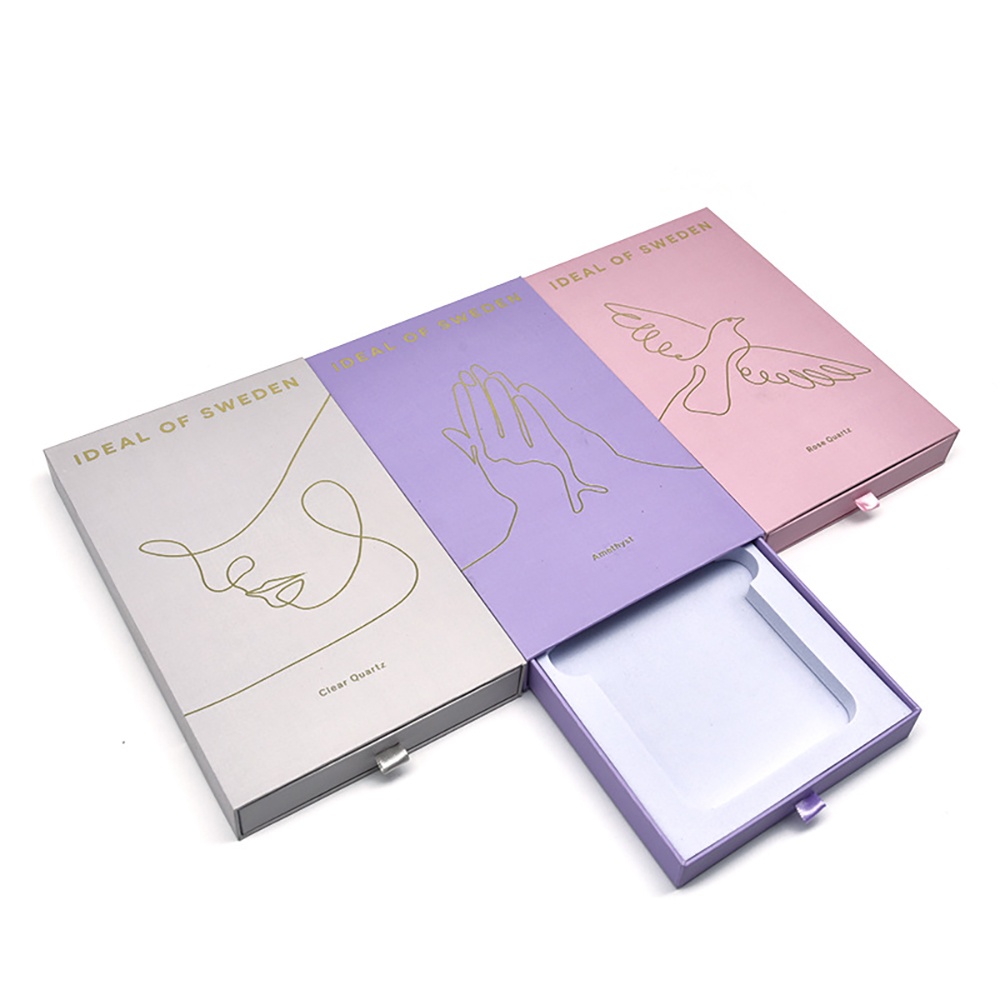

2. Visuals and Craftsmanship: Dual Drivers of Brand Premium and Emotional Resonance

- Foil Stamping Technique Enhancing Brand Recognition

- Utilises micro-engraved foil stamping technology to present the brand logo in the centre of the box lid, with line precision reaching 0.1mm, maintaining clear gloss under bright light and enhancing visual recognisability by 30%.

- The foil stamping is layered with a UV protective coating, improving wear resistance by 50%, preventing damage from frequent use.

- Application of Purple Colour Psychology

- Selects Morandi matte purple as the primary colour, with saturation controlled at 60%-70%, effectively reducing visual fatigue while stimulating a “mysterious unboxing anticipation”.

- The box surface features a matte finish, providing a delicate touch and avoiding fingerprint residue, aligning with the high-end cosmetic aesthetic.

3. Functional Details: Dual Assurance of Durability and Adaptability

Integrated Ribbon Pull Tab Design

- The ribbon is made of high-density nylon weaving, with a metal reinforcement ring embedded at the connection point to the box, achieving a pull strength of 50kg, ensuring no deformation or detachment after multiple pulls.

- The curvature of the pull tab fits the finger’s contour, increasing opening comfort by 40%.

4. Rapid Sampling Service: 72-Hour Full Process Delivery

Standardised Sampling Process

- 24-Hour Design Refinement: Generates 3D modelling images based on customer sketches, simultaneously outputting material, craftsmanship, and colour parameter plans.

- 48-Hour Physical Verification: Utilises CNC moulds to carve the lining, concurrently completing foil stamping colour calibration, sliding rail load testing, and drop simulation.

- Fully Visual Tracking: Customers can view sampling progress in real-time through a cloud system and confirm details online.

Applicable Scenarios

- High-End Skincare Gift Boxes: Suitable for glass-bottled products such as serums and creams, providing shock resistance and breakage prevention.

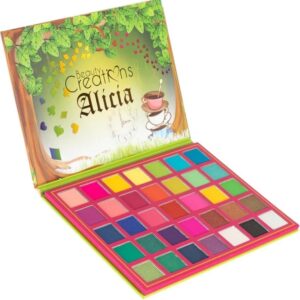

- Makeup Sets: Secures irregular items like eyeshadow palettes and brushes, preventing damage during transport.

- Limited Edition Collaborative Products: Enhances IP collaboration visual impact through foil stamping and purple colour schemes.