Your Custom Clothing Packaging Box Comprehensive Guide

Master custom apparel boxes! This essential guide covers design, materials,

Get custom paper boxes & branded packaging made easy! Our experts provide dedicated support. Benefit from low minimums, low prices, fast turnaround, a free sample, and free design service. Elevate your brand without breaking the bank.

Master custom apparel boxes! This essential guide covers design, materials,

Navigate food packaging with ease! This guide covers design, materials,

In today’s fast-paced industrial world, paper boxes have actually become a keystone of reliable, sustainable, and versatile packaging solutions . Whether you’re a company delivering products worldwide or a regional business aiming to impress consumers , comprehending the worth of paper-based product packaging is important. This post dives deep into the industrial applications of paper boxes , checks out how they’re designed and manufactured, and exposes why they’re essential for safeguarding products , boosting branding, and meeting client demands. If you’re looking to maximize your plan strategy, decrease costs, or straighten with eco-friendly patterns, this guide is your roadmap to grasping the art and science of box product packaging .

Paper boxes dominate the commercial product packaging landscape completely reason. They strike an equilibrium in between affordability, durability, and environmental duty. Unlike plastic or metal alternatives, paper is sustainable, recyclable, and biodegradable, making it optimal for business intending to satisfy sustainability goals. From food distribution to deluxe item product packaging, paper boxes adjust to different industries thanks to their customizable design , dimension , and print choices.

In addition, paper boxes are cost-efficient to produce at scale. Advanced producing methods permit companies to produce light-weight yet durable packages that protect goods during transportation. Whether it’s corrugate board for durable deliveries or streamlined cardboard for retail screens, paper boxes cater to varied customer requires while keeping cost factors competitive.

A competent box design team is the backbone of reliable product packaging remedies . These product packaging experts team up with customers to translate brand name visions into useful styles . For example, architectural engineers make sure the box can stand up to weight and folding tensions, while visuals designers concentrate on art work and color accuracy to boost shelf charm.

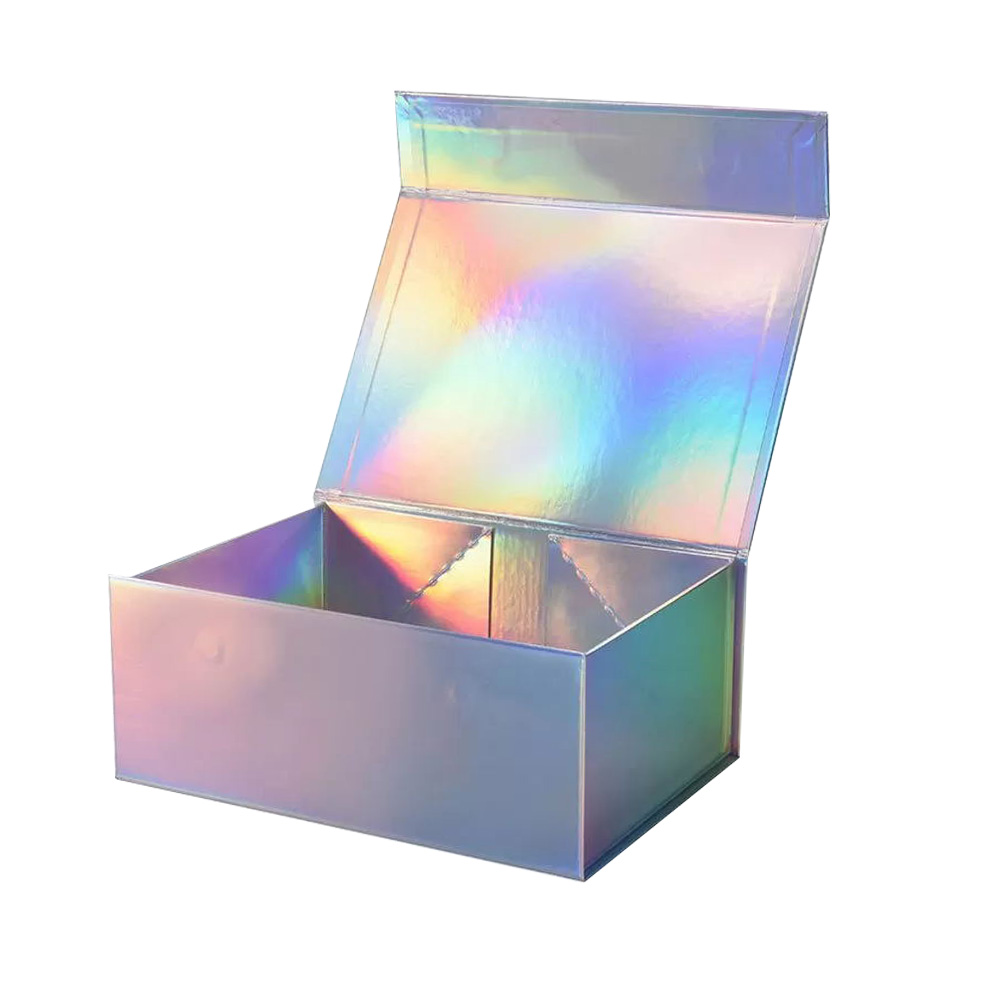

The group likewise considers customer logistics, such as maximizing box dimension to decrease delivery prices or incorporating easy-open features. By aligning design with product specifications , the box style team makes sure that product packaging not just secures yet likewise raises the unboxing experience.

Selecting the appropriate material is critical for paper box efficiency. Corrugate board, with its fluted inner layer, provides superior toughness for hefty products , while strong board is excellent for premium print surfaces. Firms often make use of folding carton boards for lightweight products like cosmetics or food , stabilizing flexibility and rigidity.

Material quality also issues. As an example, moisture-resistant coatings secure plans in moist atmospheres, and food-safe products ensure conformity with wellness standards. By matching product residential or commercial properties to product needs , business boost durability without overengineering product packaging .

Specifications such as dimension , weight , and structure directly influence packaging performance. A box that’s too large rises delivering costs and waste, while one that’s also small risks damaging the item . Business rely upon accurate dimension calculations and weight examinations to strike this balance.

Custom-made specs also accommodate niche requirements. For instance, folding tabs may be added for simple assembly, or strengthened sides for stacking. By customizing box specifications to customer workflows, product packaging ends up being a seamless extension of the item itself.

High-grade print changes paper boxes right into effective branding tools. Offset printing delivers dynamic shades and sharp art work , while digital printing allows for little orders with variable styles . Specialized surfaces like embossing or UV finishes include tactile and visual deepness.

Art work authorization is a crucial action below. Clients function carefully with print teams to guarantee logo designs, text, and shade plans line up with brand standards. A well-printed box not just catches the eye however also interacts quality and professionalism.

High quality control starts with strenuous product screening and includes every manufacturing phase. Firms conduct crush tests to verify box stamina and examine print precision versus art work proofs. Sampling is important– customers typically request box prototypes to authorize before full-blown making .

Automated systems additionally keep track of manufacturing lines for flaws like misaligned folding or adhesive gaps. By focusing on high quality , firms reduce returns and develop trust fund with consumers .

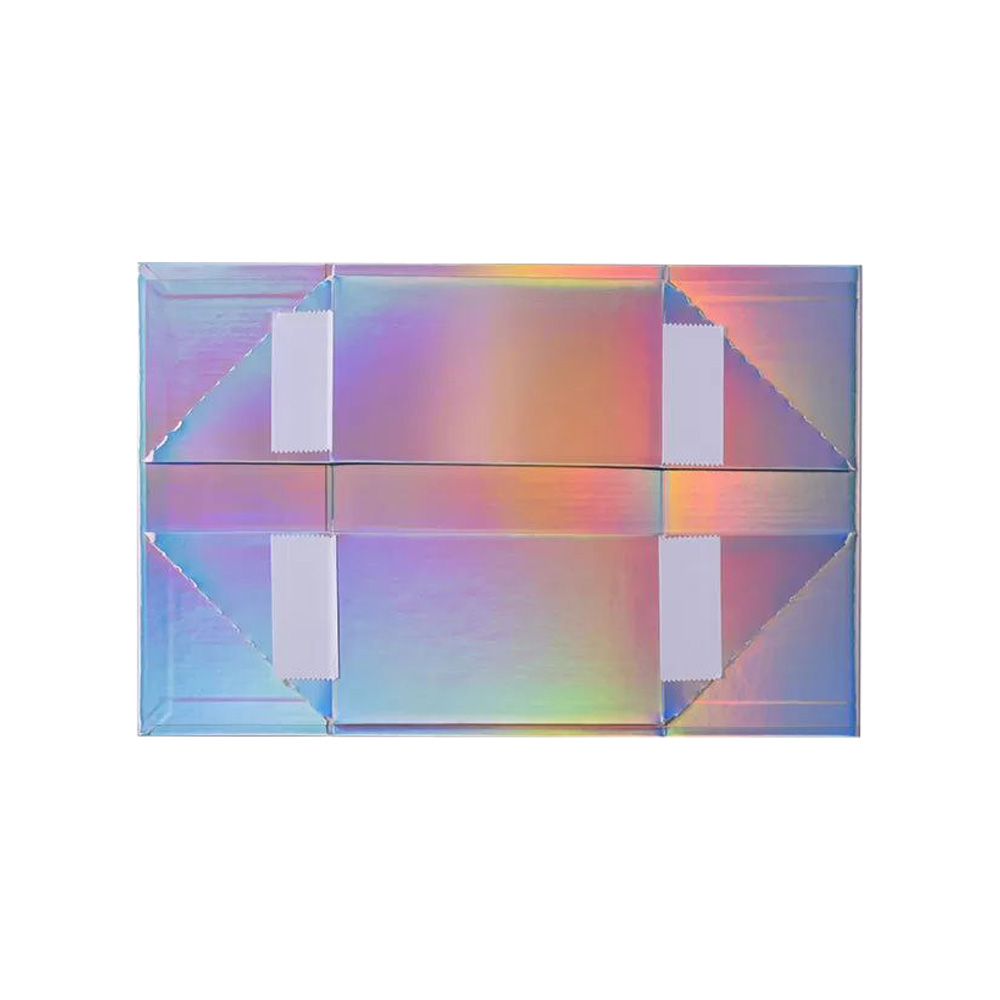

Folding strategies simplify box setting up and reduce labor prices. Die-cutting machines precision-score paper sheets, making it possible for fast folding into final shapes. This process is specifically essential for intricate styles , such as lock-bottom boxes or interlacing screens.

Effective folding likewise minimizes storage area. Flat-packed boxes are easier to ship and save, lowering logistical expenditures for firms .

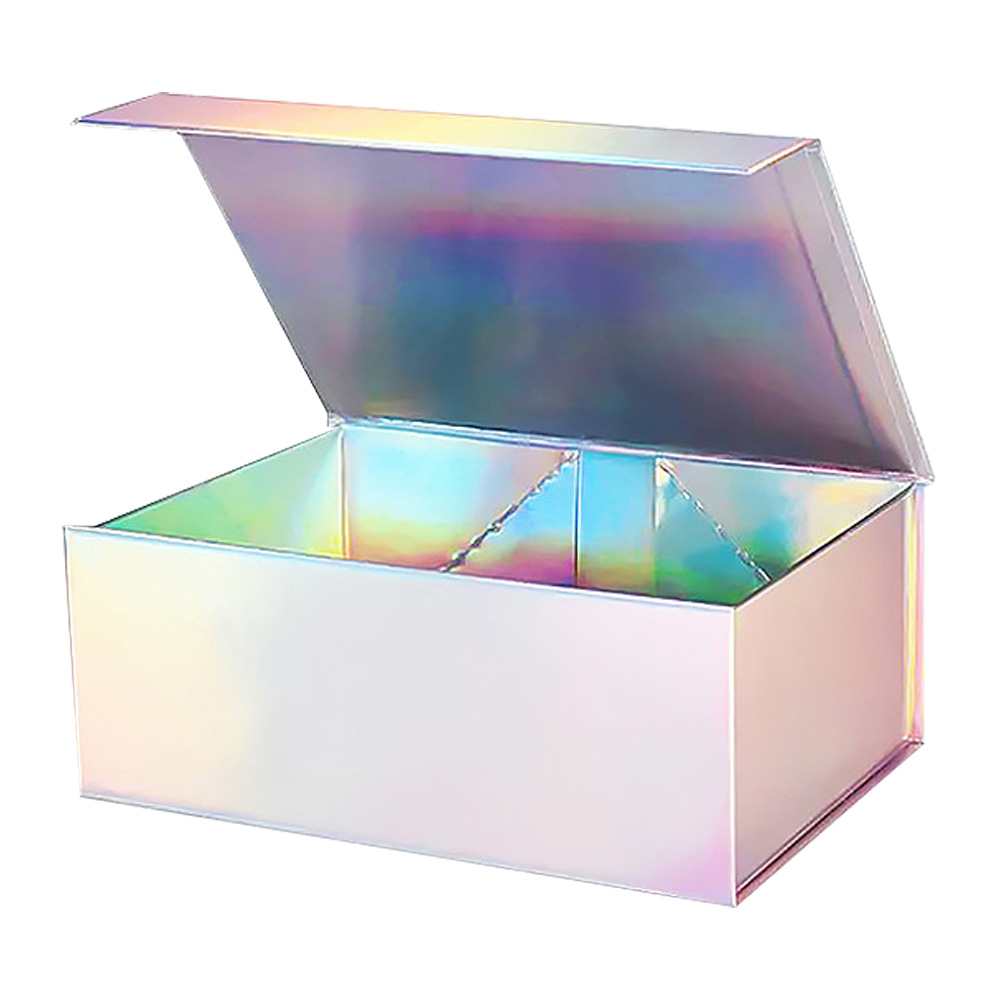

Modification is where paper boxes shine. A consumer might need boxes with windows for food items, magnetic closures for luxury items, or eco-friendly products for conscious brand names. Product packaging specialists make use of CAD software program to version designs and run simulations for size , weight , and toughness.

Even tiny orders benefit from tailored solutions. Whether it’s an one-of-a-kind print surface or a bespoke framework , custom boxes help business stick out in congested markets.

Sustainability drives innovation in paper boxes . Recycled products , soy-based inks, and eco-friendly finishings are currently industry standards. Companies also take on minimal layouts to minimize waste and carbon impacts.

Another pattern is recyclable product packaging . Clients significantly prefer boxes that can be repurposed, straightening with circular economy concepts.

Picking a firm with experience in your sector is vital. Search for product packaging specialists that use end-to-end services, from layout to shipment . Check their production capacities, product options, and customer support responsiveness.

Always demand samples and evaluation artwork approval processes. A reliable partner will certainly make certain your boxes fulfill requirements , top quality requirements, and timelines.

Fill out the form below and we will contact you within 10 minutes.