Abstract

Driven by a dual awareness of global environmental protection and consumption upgrades, paper materials have gradually become the core choice in the gift packaging sector due to their biodegradability, design flexibility, and cost-effectiveness. This article systematically demonstrates why paper packaging is recognised as the best solution for gift wrapping from four dimensions: environmental sustainability, visual and tactile experience, production efficiency, and market adaptability, combining industry data and technological innovation cases, while exploring its commercial potential in a global context.

1. Environmental Sustainability: The Ecological Mission of Paper Packaging

1.1 Practices of Biodegradability and Circular Economy

Paper materials come from renewable forest resources, and their production process reduces carbon emissions by over 60% compared to plastics. Taking FSC-certified paper as an example, its supply chain achieves a dynamic balance of forest resources, with each tonne of recycled paper saving 4 cubic metres of timber. Globally renowned brands such as Apple have reduced their product carbon footprint by 34% by using 100% recycled fibre packaging boxes, confirming the core position of paper packaging within the circular economy.

1.2 Pollution Control and Ecological Benefits

In comparison to traditional plastic packaging, paper materials have a degradation period of only 2-6 months in the natural environment, with decomposition products being harmless carbon dioxide and water. A European Union research report indicates that promoting paper packaging could reduce marine plastic pollution by 27%. Practices from China’s paper gift packaging projects demonstrate that using water-based inks and non-glue composite processes has led to a 90% reduction in VOC emissions during the packaging production phase, highlighting its technological advantages in pollution control.

2. Design Empowerment: The Sensory Revolution of Paper Packaging

2.1 Infinite Possibilities in Visual Presentation

The high print suitability of paper materials supports multiple processes such as lithography, gold hot stamping, and Spot UV embossing. For example, GUCCI’s limited edition perfume gift box uses pearl paper and partial embossing techniques, enhancing the packaging’s gloss by 40% and successfully creating a luxury-grade visual impact. Research shows that 72% of consumers are more willing to purchase due to exquisite packaging design, and paper materials, with a colour reproduction rate of 98%, can significantly enhance brand recognition.

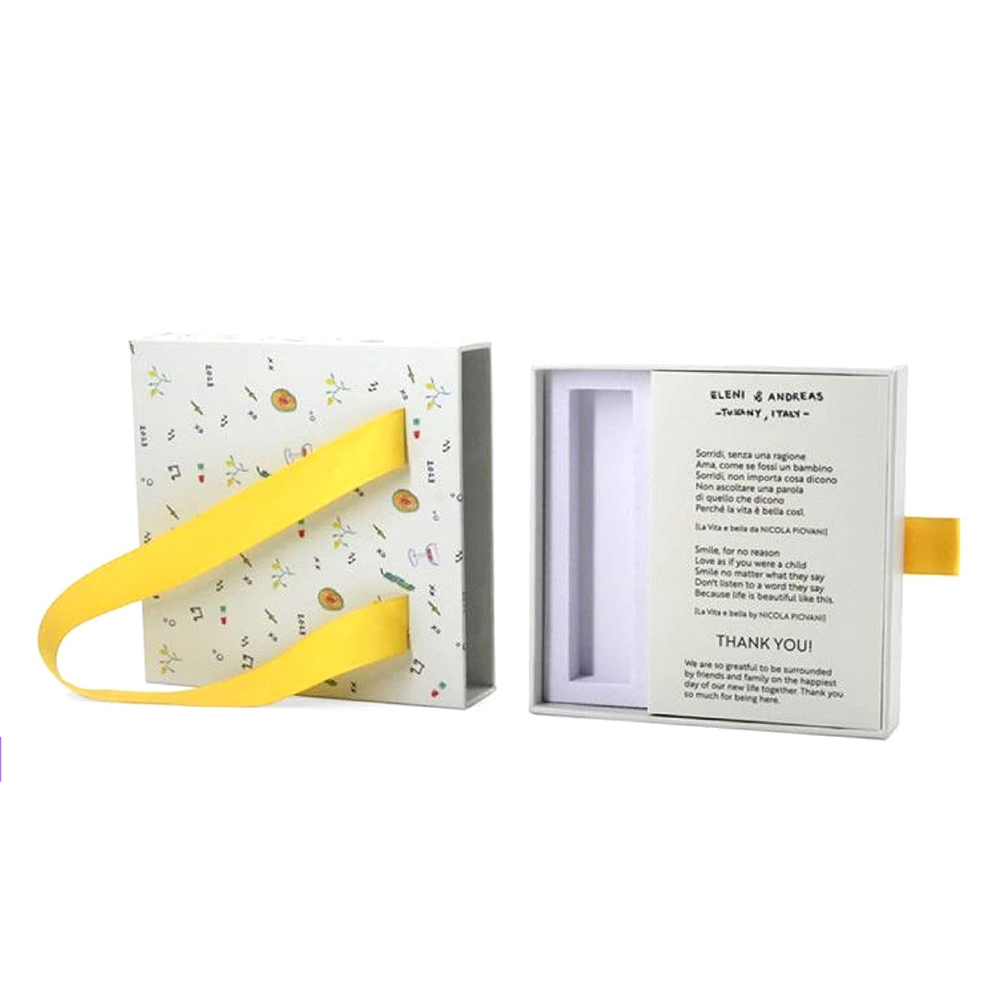

2.2 Structural Innovation and User Experience

From lid and base boxes to collapsible gift boxes, paper packaging achieves over 200 structural variations through die-cutting and slotting technology. Japanese designer Naoto Fukasawa introduced a “growable” seed paper gift box, allowing users to bury the packaging in soil to cultivate plants after unboxing, transforming functional packaging into an emotional interaction medium. Such designs not only reduce logistics space occupancy by 30% but also enhance the unboxing experience through textured paper.

3. Cost and Efficiency: The Win-Win Logic of the Industry Chain

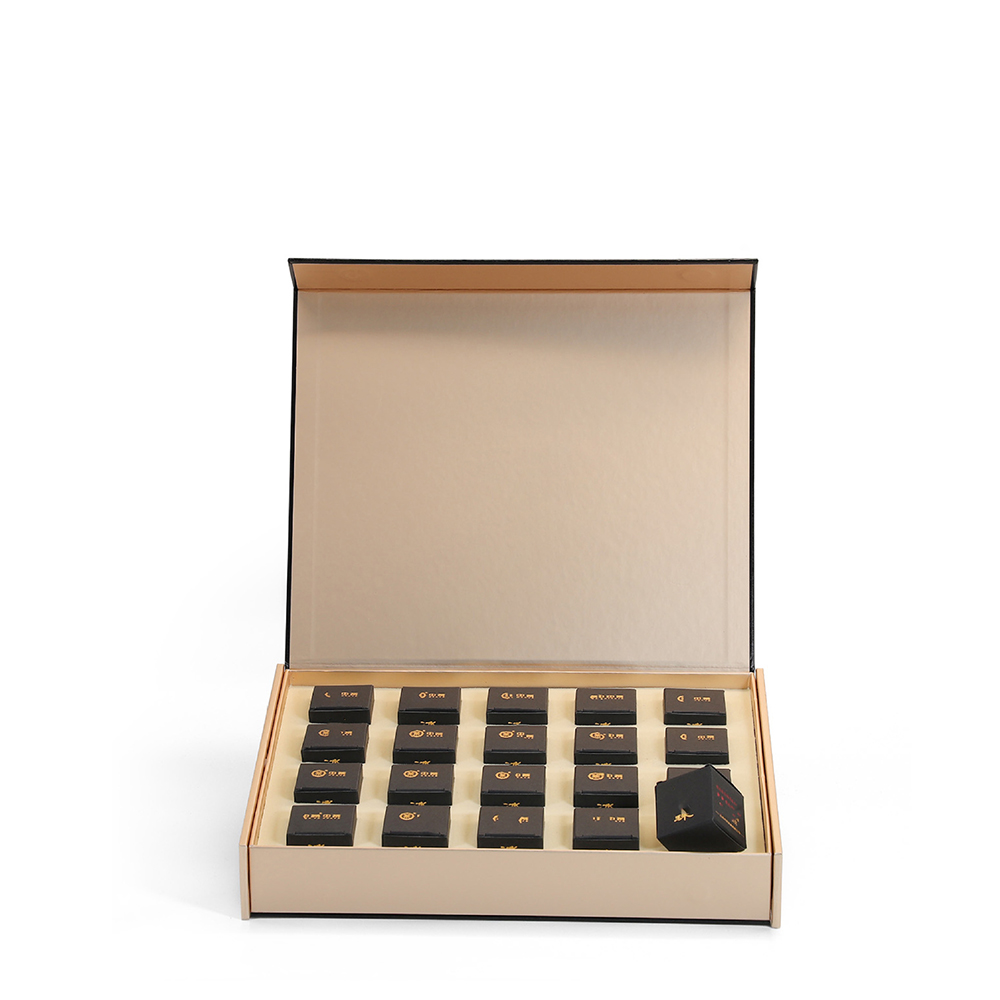

3.1 Economic Efficiency of Scaled Production

The raw material cost of paper packaging is only 1/5 that of metal materials and 1/3 that of plastics, and automated gluing production lines can achieve a daily output exceeding 100,000 units, reducing labour costs by 45%. One company optimised its mooncake gift box production using rigid paper forming technology, leading to an 18% reduction in production costs, while customers’ willingness to pay a premium increased by 22%.

3.2 Hidden Benefits in Logistics and Storage

Paper packaging is, on average, 63% lighter than comparable wooden products, resulting in a 40% increase in the loading capacity of a standard shipping container. IKEA has reduced its global transport loss rate from 1.2% to 0.3% through modular cardboard box design, saving over $20 million in logistics costs annually.

4. Market Adaptation: Strategic Choices in the Wave of Globalisation

4.1 Policy-Driven Market Expansion

After China’s accession to the WTO, the annual demand for packaging of export goods grew by 12%, with the penetration rate of paper packaging for food and electronic products reaching 78%. The EU’s “Green New Deal” mandates the elimination of single-use plastic packaging by 2030, creating a trillion-yuan alternative market for paper packaging.

4.2 Precise Alignment with Consumer Mindsets

According to a Nielsen survey, 83% of Generation Z consumers are willing to pay a 5%-10% premium for environmentally friendly packaging. Starbucks, through its FSC-certified paper cup programme, saw a 9% increase in annual sales, and its brand ESG rating soared to the top three in the industry. This “green premium” mechanism positions paper packaging as a dual lever for companies to fulfil social responsibility and achieve business growth.

Conclusion

The dominant position of paper materials in the gift packaging sector stems from their precise grasp of eco-friendliness, aesthetic expression, production efficiency, and market dynamics. From innovations in biodegradable technology to the development of smart packaging systems, this material is continually breaking traditional boundaries. With the improvement of global carbon tariff mechanisms and the deepening of consumer awareness of environmental protection, choosing paper packaging has become not only a business decision but also a strategic investment in a company’s future competitiveness.