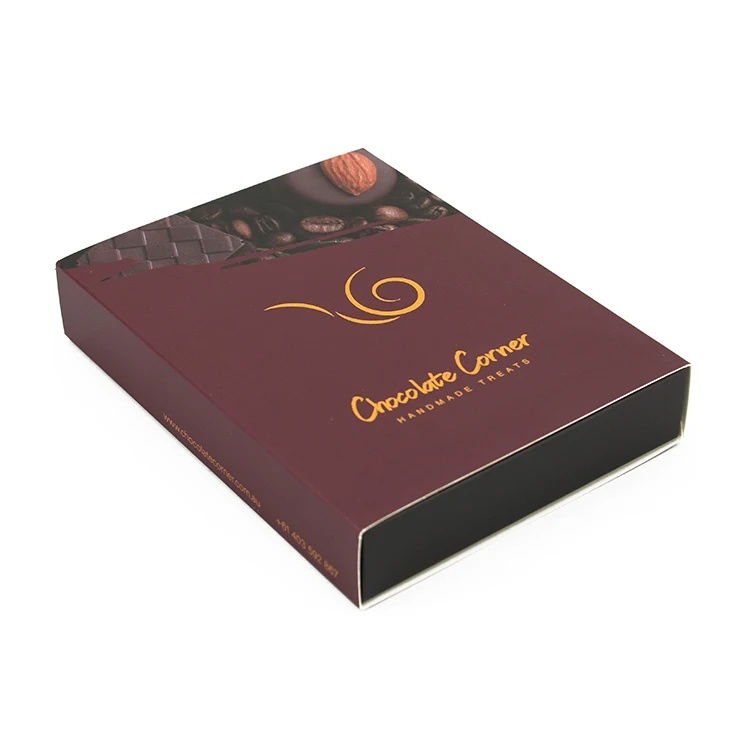

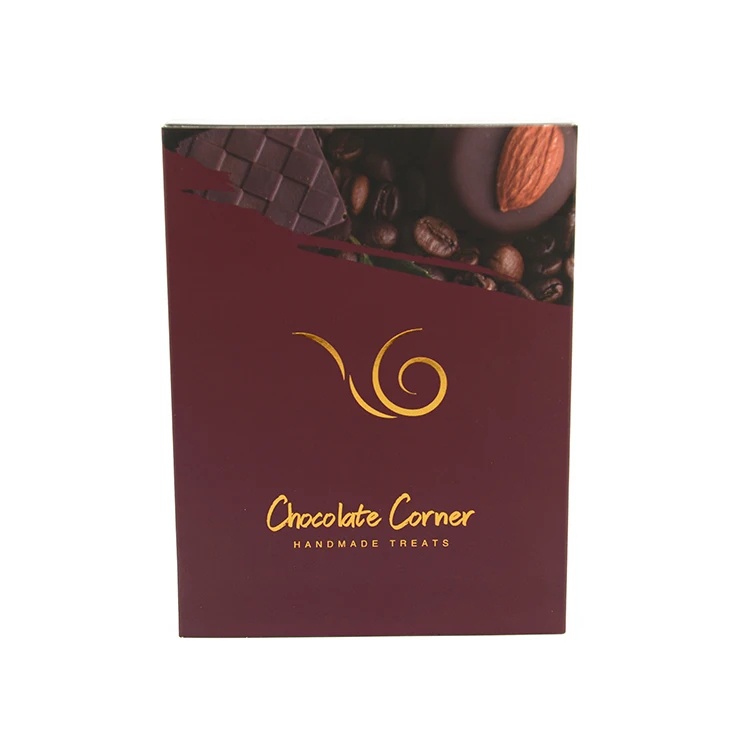

Personalised Custom Slider Chocolate Cookie Macaron Box

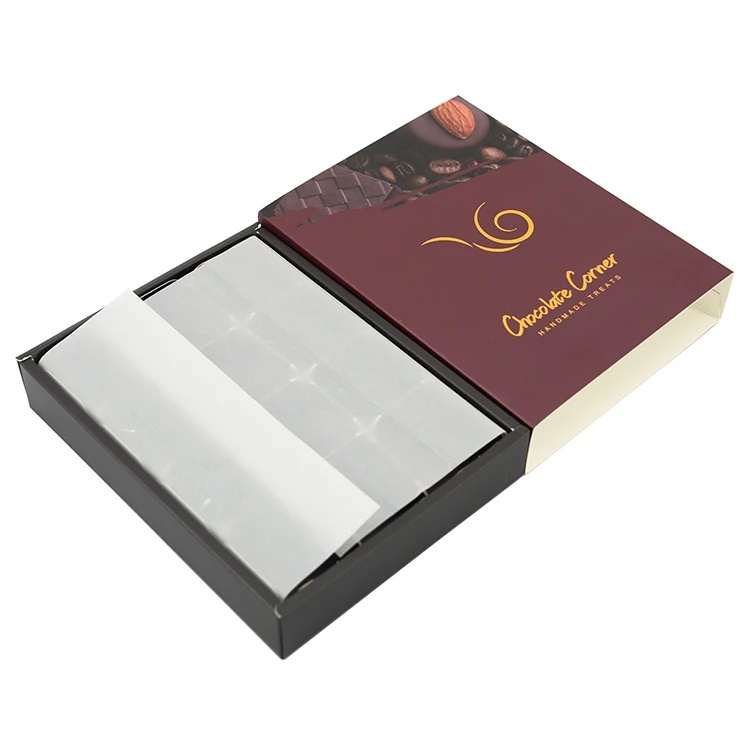

The slider box conforms to the classic aesthetic of chocolate gift packaging. The innovative 12-grid partition system allows a single box to accommodate multiple categories specifications of products, making it suitable for combination packaging scenarios.

Description

Personalised Custom Chocolate Cookie Macaron Slider Box Product Description

1. Food Contact Grade Materials, Safe and Compliant

Both the box and the lining are made from materials that meet food-grade standards, tested for migration levels, heavy metal leaching, and fluorescent whitening agents. The product packaging clearly labels “For Food Contact” along with the material name (e.g., “Food-Grade Art Paper”), production licence number, and compliance declaration, ensuring safety and regulatory compliance.

2. Ultra-High Pressure Creasing Technology, Precise Fold Line Location

Utilising ultra-high pressure creasing technology, precise pressure is applied at the pre-creased lines of the cardboard using CNC equipment, creating consistently deep, invisible creases. This technology avoids the fraying or breaking issues often associated with traditional die-cut creasing, ensuring that the box folds neatly with crisp edges and smooth opening and closing, while also enhancing compressive strength (with a load capacity of up to 5kg).

3. Polished Rounding of Edges for Enhanced Touch

The edges of the box undergo CNC grinding for R-angle polishing (radius 0.5-1mm), eliminating burrs and creating rounded surfaces. The polished surface has a roughness of ≤Ra1.6μm, providing a delicate and smooth touch, preventing hand injuries. The lining partition pieces also feature rounded designs, closely fitting the contours of fragile items like chocolate cookies, further reducing the risk of damage during transport.

4. Efficient CNC Cutting, Rapid Sample Production in 60 Minutes

Equipped with five high-precision CNC cutting machines (cutting accuracy ±0.1mm), this setup supports bulk automated die-cutting and custom profile processing. The FastCAM nesting software optimises layout, increasing material utilisation to over 95%. Once the client provides the design file, the system automatically generates cutting paths and simultaneously initiates multi-machine collaboration, achieving complete production from design to sample within 60 minutes, meeting urgent order demands.