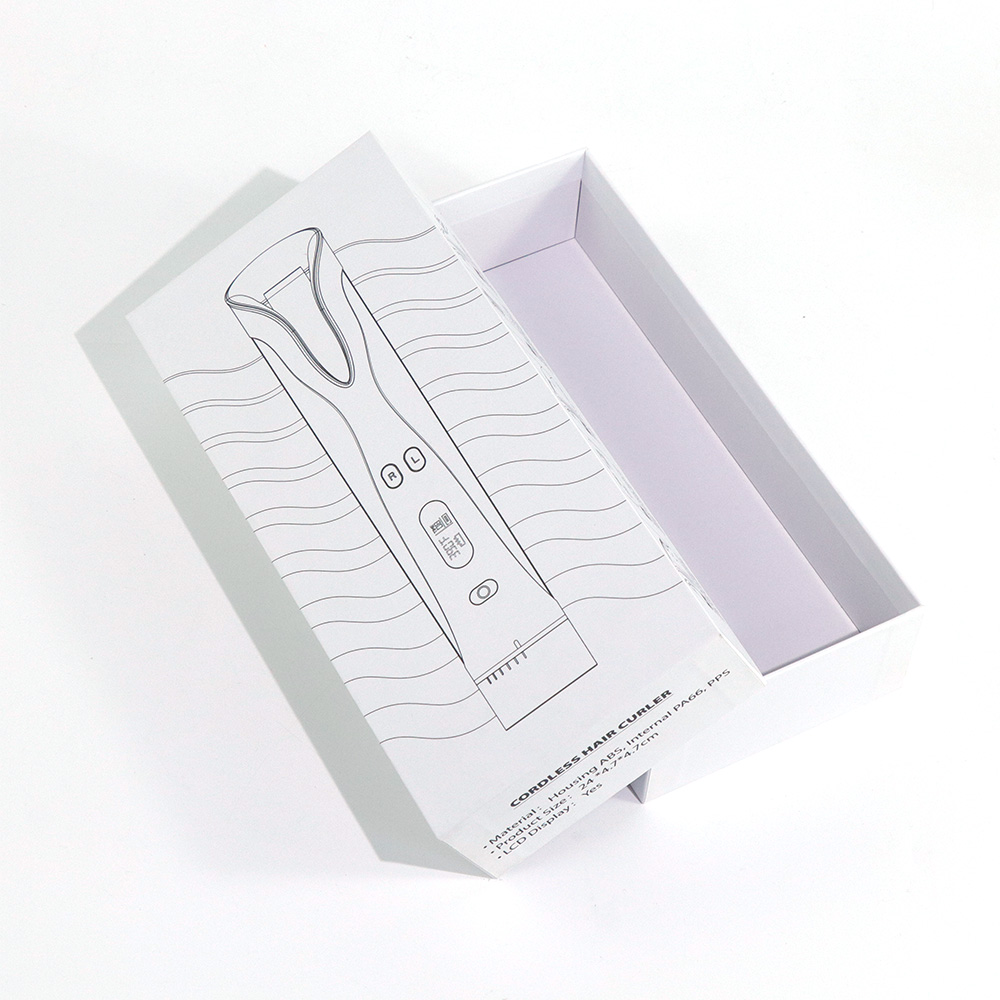

Premium Customized Gift Lid and Base Boxes for Curling Irons

It adopts the classic top and bottom box cover structure. The box is easy to open and close and fits tightly. The upper and lower covers are very stable, and there is no redundant decoration on the box body. It conforms to the current minimalist style and is very suitable for the packaging of your curling irons and other products.

Description

High-End Custom Curling Iron Gift Box Product Description

1. Structural Design: Revolutionary Innovation of the Classic Top and Bottom Box

Utilising a classic top and bottom box structure, the product is crafted through modular precision moulding, allowing for smooth opening and closing of the box lid with a fit tolerance of ±0.2mm. Compared to traditional magnetic closure boxes, the box body achieves a 30% increase in compressive strength through a five-layer grey board composite process, with a vertical load capacity of 15kg, ensuring the box remains undistorted during transit. The box base features an integrated honeycomb reinforcement structure that can disperse over 60% of impact forces during transport, effectively protecting the internal curling iron and accessories.

2. Craftsmanship Precision: Industrial-Grade Moulds and Seamless Welding

The box body is manufactured using ±0.02mm ultra-precision moulds, with joint tolerances controlled to aerospace standards. Coupled with ultrasonic high-frequency welding technology, the seam flatness error is maintained at ≤0.1mm, completely eliminating burrs and glue overflow issues. The edge lines are treated with 3D CNC grinding technology, achieving a surface smoothness of Ra ≤0.4μm, providing a silky touch. The rounded corner design is ergonomic, preventing scratches during handling.

3. Visual Aesthetics: Balance of Minimalism and Functionality

Adhering to the Less is More design philosophy, the box body features no redundant decorations, conveying a sense of luxury solely through the natural texture of the materials. Options include plain laser paper, textured velvet film, or eco-friendly soy ink printing, supporting transitions between matte, glossy, and metallic finishes. The box shape has been optimised with golden ratio cutting, making it suitable for various display needs in supermarkets, e-commerce logistics, and more, enhancing visual recognition by 40%.

4. Customisation Services: Deep Adaptation to Brand Needs

- Box Shape Customisation: Offers 12 basic box shapes including square, hexagonal, and custom cuts, with support for 3D structural modelling and rapid prototyping;

- Material Selection: Includes eco-friendly options such as FSC certified grey board, biodegradable sugarcane fibre board, and metal composite board, with hardness ranging from 20-80 Shore A;

- Printing Techniques: Supports over 20 combinations of techniques including foil stamping, embossed UV, spot gloss, and magnetic closures, with Pantone colour matching precision of ΔE ≤1.5;

- Functionality Expansion: Capable of integrating NFC chip slots, anti-counterfeit label layers, LED ambient light strips, and other smart modules.

5. Quality Control System: Comprehensive Quality Assurance

- Mould Inspection: A coordinate measuring machine (CMM) monitors the positional tolerances of the mould throughout the process, ensuring batch consistency;

- Production Traceability: Each batch of packaging includes an independent QR code for tracing raw material suppliers, production times, and quality inspection reports;

- Transport Testing: Conducted under ISTA 3A standards to simulate vibration, drop, and temperature/humidity cycling tests, with a damage rate of <0.3%.

Application Scenarios: High-end hair tool gifts, brand collaboration limited editions, high-ticket cross-border e-commerce products.

Environmental Commitment: Utilising water-based adhesives and solvent-free printing, 100% recyclable or compostable.