Current State of the Packaging Industry Under Tariff Pressures

Fluctuations in global trade policies are having a profound impact on the packaging supply chain. Custom packaging supply chains relied upon by US companies are facing soaring costs and unstable supplies due to a surge in tariffs. For instance, under the China-US tariff policies, the import costs of certain packaging materials have increased by 145%, leading to a 20%-40% reduction in profits for small and medium-sized enterprises. This environment is forcing businesses to reassess their packaging strategies, shifting from a solely cost-oriented approach to a comprehensive decision-making process that balances risks and benefits.

Threefold Challenges of Tariffs for Custom Packaging Companies

1. Cost Control and Supply Chain Disruption

- Increased Price Volatility: As a major supplier of packaging materials, China’s export restrictions are forcing US suppliers to pass on costs.

- Decreased Supply Stability: Tariff-induced logistics delays have extended packaging delivery cycles from an average of 4 weeks to 8 weeks, directly affecting sales rhythms for businesses.

2. Reduced Design Flexibility

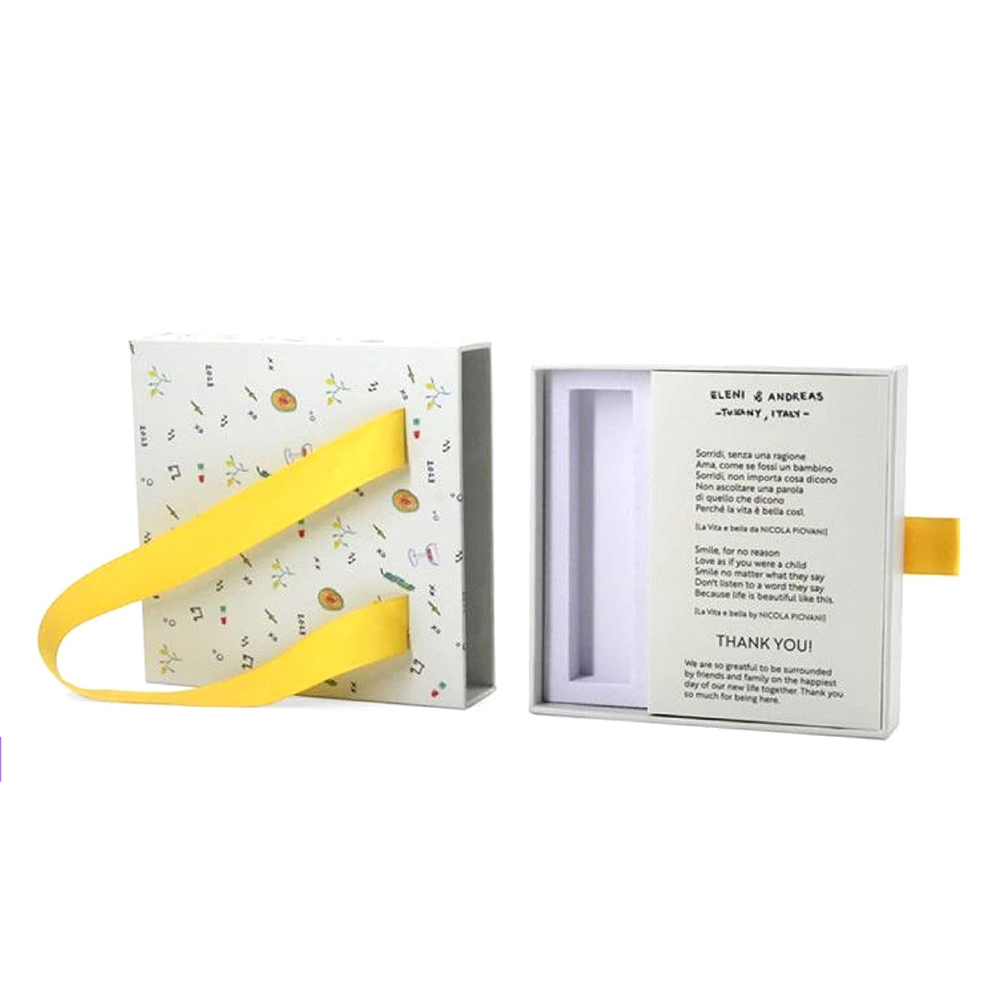

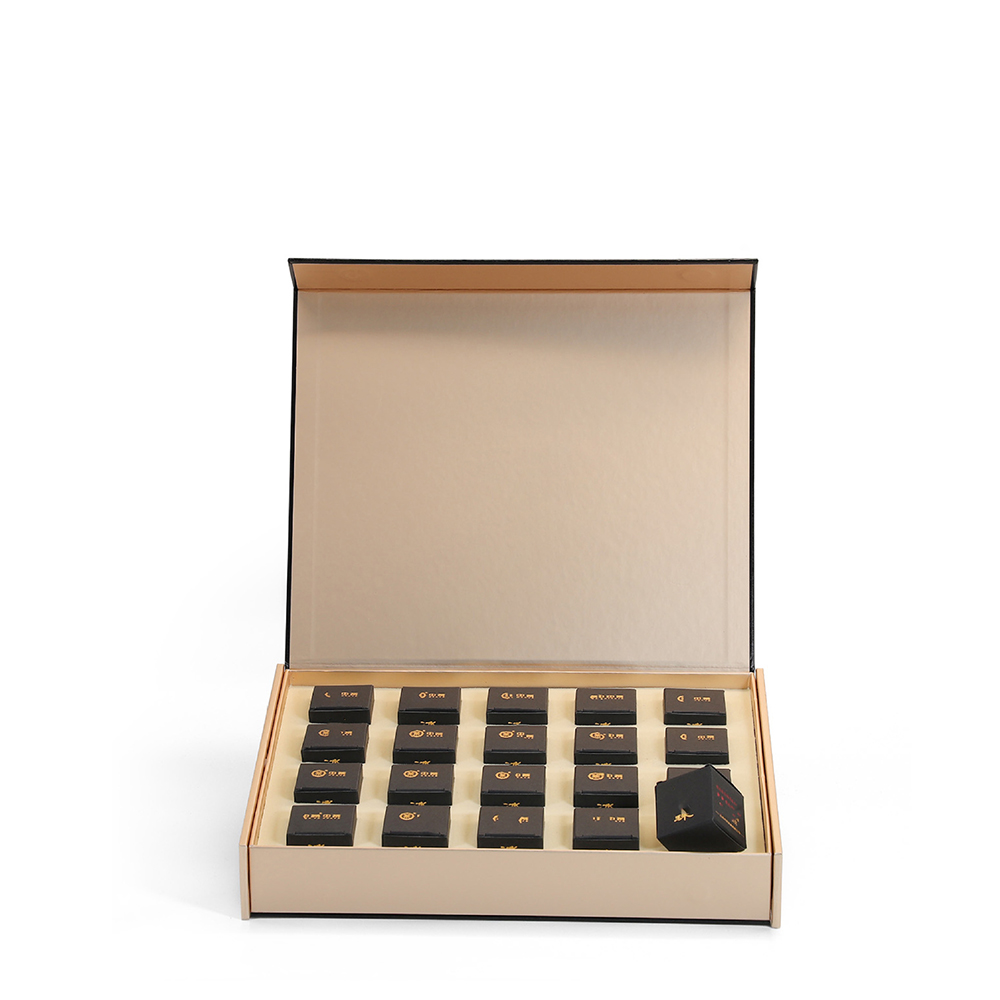

- A contraction in supplier inventories has led to a reduction of over 50% in custom options, limiting high-end processes such as foil stamping and bespoke box designs.

- AI design tools can quickly generate alternative solutions through semantic analysis, but they require human review to ensure brand consistency.

3. Structural Changes in Market Demand

- Consumers are becoming more sensitive to price increases; research indicates that after costs are passed on, 67% of brands experience a decline in average transaction value.

- Amid expectations of economic recession, searches for environmentally friendly packaging solutions have risen by 120%, reflecting a shift in consumer preferences towards practicality.

Breakthrough Strategy: Four Steps to Build a Tariff-Resilient Packaging System

1. Upgrading Supply Chain Resilience

- Multi-Regional Procurement Network: Prioritise suppliers with production bases in Southeast Asia (Vietnam, Thailand) and Mexico to diversify tariff risks. Case studies show that companies adopting a “China + ASEAN” dual-source procurement strategy have reduced cost fluctuations by 40% in 2024.

- Digital Supplier Assessment: Utilise Google’s similarity algorithms to analyse supplier financial reports and tariff plans, selecting partners with high transparency.

2. Design Optimisation and Cost Control

- AI-Driven Lightweight Design: Use Generative Adversarial Networks (GAN) to simulate protective performance after reducing material thickness by 20%, with actual tests showing only a 1.2% increase in transport damage rates, saving 18% in tariff costs.

- Modular Packaging Systems: For example, a cosmetics brand separates the outer box from the inner tray design, allowing different product specifications to share a base box design, reducing mould costs by 60%.

3. Dynamic Cost Management Model

- Establish a tariff sensitivity analysis system to simulate the financial impact of tax rates ranging from 25% to 200%. Tools indicate that when tax rates exceed 100%, using recycled plastics is more cost-effective than traditional PET.

- Bulk Purchasing Hedging: By using Google AI demand forecasting tools, locking in quarterly usage can achieve discounts of 5%-12%.

4. Policy Response and Compliance Innovation

- Deep Application of Duty-Free Codes: For example, recycled plastic packaging under HTS code 3923.90 enjoys a 3% tariff reduction, saving companies over $120,000 per year in successful applications in 2023.

- Free Trade Zone Processing Model: Completing final packaging assembly at factories near the Mexican border utilising the USMCA agreement to achieve “zero-tariff finished goods into the US.”

Technological Empowerment: Our Intelligent Solutions

1. Tariff Simulation System

- Integrate real-time trade databases to predict tax rate fluctuations over the next six months, automatically generating three cost optimisation plans.

2. Material Substitution Engine

- Match over 200 duty-free alternative materials based on semantic similarity algorithms. For instance, a food company replaced Chinese corrugated paper with Brazilian eucalyptus pulp board, maintaining strength while reducing tariff costs by 29%.

3. Logistics Path Optimisation

- AI calculates the lowest total cost route: a combination of land transport between China and Vietnam and sea transport to the US West Coast, resulting in only a 2-day increase in logistics time for an electronic brand, while reducing tariff expenditures by $87,000 per year.

Conclusion: Reconstructing Packaging Competitiveness with Agility

The tariff crisis is fundamentally an exposure of supply chain vulnerabilities. Through a triadic strategy of “intelligent design + flexible procurement + data-driven decision-making”, businesses can compress the proportion of packaging costs from 12% to below 8% (industry benchmark data).