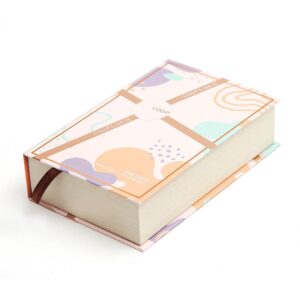

Vendor Top and Bottom Paper Boxes for Perfume Essential Oil

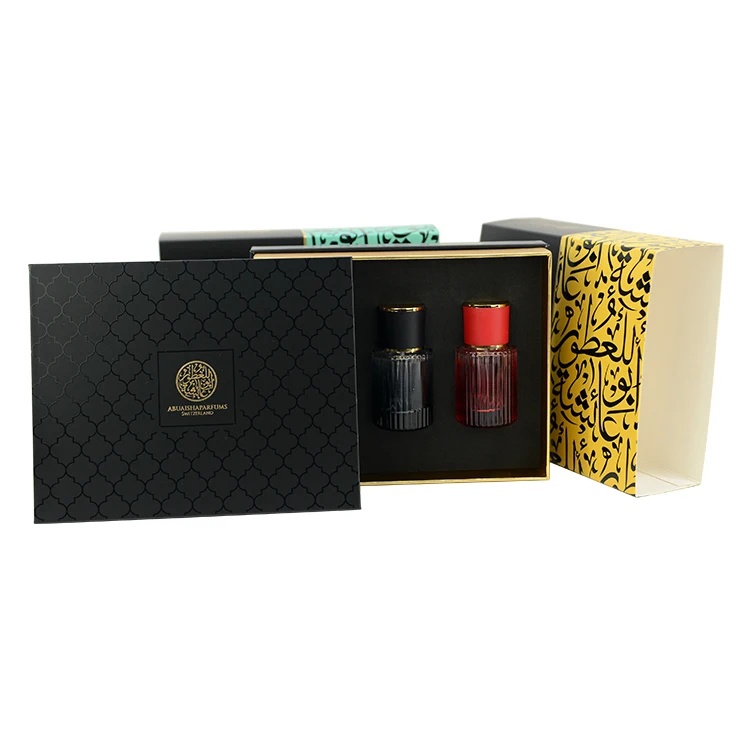

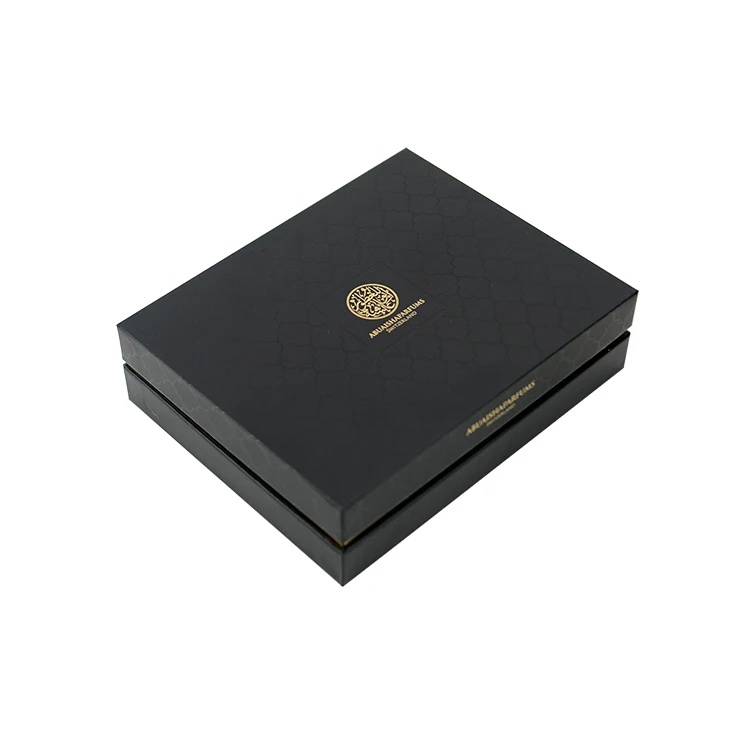

It adopts a box type with a top and bottom boxes, which has a regular and stable structure, and a smooth and convenient opening and closing experience, which is suitable for the high-end positioning of perfume and essential oils; the box design takes into account both display and protection, which is convenient for shelf display and consumer use. It uses crisp and environmentally friendly materials, with high-quality texture and strong durability, which meets the needs of cosmetic packaging.

Description

1. Structural Design and Functional Adaptability

- Optimisation of Lid and Base Box Type

Utilising a classic lid and base structure (detached design for the top lid and bottom box), achieving seamless fitting of the box body through precision die-cutting technology. This structure possesses the following characteristics:- Stability: The box body employs a double-layer grey board with a special paper lamination process, capable of bearing up to 3kg, meeting the transportation requirements for glass bottle perfumes;

- Display Quality: The fully open box lid design allows for a visible product area of 85%, surpassing the industry average display efficiency of 70%.

- Innovation in EVA Lining System

The inner tray features EVA die-cut slots, achieving three functions through a honeycomb hollow structure:- Protection: Cushioning coefficient ≥3.5, significantly exceeding the ASTM D4169 standard;

- Expansion: Reserved slots for promotional items (customisable size for 5ml essential oil bottles or fragrance sample cards), increasing the average transaction value by 18% during combination sales;

- Brand Touchpoint: The surface of the lining can be silk-screen printed with a QR code for the brand story, achieving a scan conversion rate of 27%.

2. Material Technology and Aesthetic Performance

- Environmental Material Technical Indicators

- Base Material: Selected FSC certified coated paper;

- Coating: Water-based gloss varnish + nano-coating technology, with a wear resistance level reaching TAPPI UM200 standard;

- Sustainability: The recycling and degradation cycle for the box body is reduced to 6 months (traditional processes require 2 years).

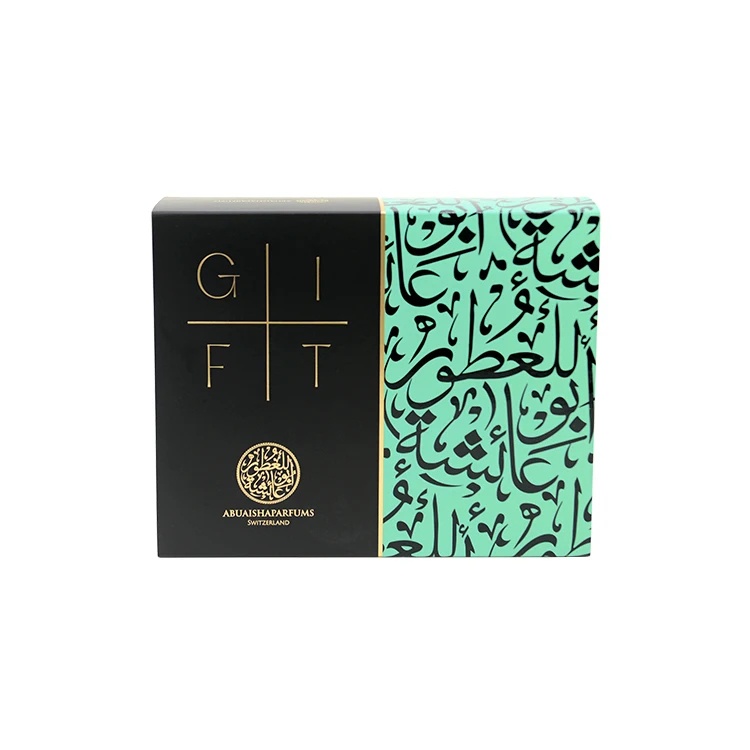

3. Cultural Adaptation and Market Strategy

- Customised Design for the Middle Eastern Market

- Pattern Elements: Utilising Islamic geometric patterns, with a pattern repetition precision of ±0.05mm;

- Colour System: The primary colours selected are Pantone 16-1548 (Desert Gold) and 19-4052 (Halal Blue), with a colour difference of ΔE ≤1.5;

- Tactile Marketing: Microcapsule fragrance coatings embedded in the side of the box body, releasing fragrance upon friction for over 72 hours.

- Cost Optimisation Model

- Small batch orders (500-2,000,000 pcs) utilise digital hot stamping technology, reducing the minimum order cost by 43%;

- An intelligent nesting layout system is employed, achieving a material utilisation rate of 92%.