Abstract

In the context of consumption upgrading and intensified brand competition, clothing packaging boxes have evolved from mere product protection tools to core carriers of brand value transmission. The Lid and Bottom Box, with its structural innovation, material diversity, and customisation potential, has become a solution that combines functionality and artistry in the shirt packaging field. This article analyses how it enhances product added value and creates differentiated competitive advantages for brands through creative applications from six dimensions: structural design, brand empowerment, and environmental trends.

1. Structural Innovation: The Perfect Balance from Protection to Display

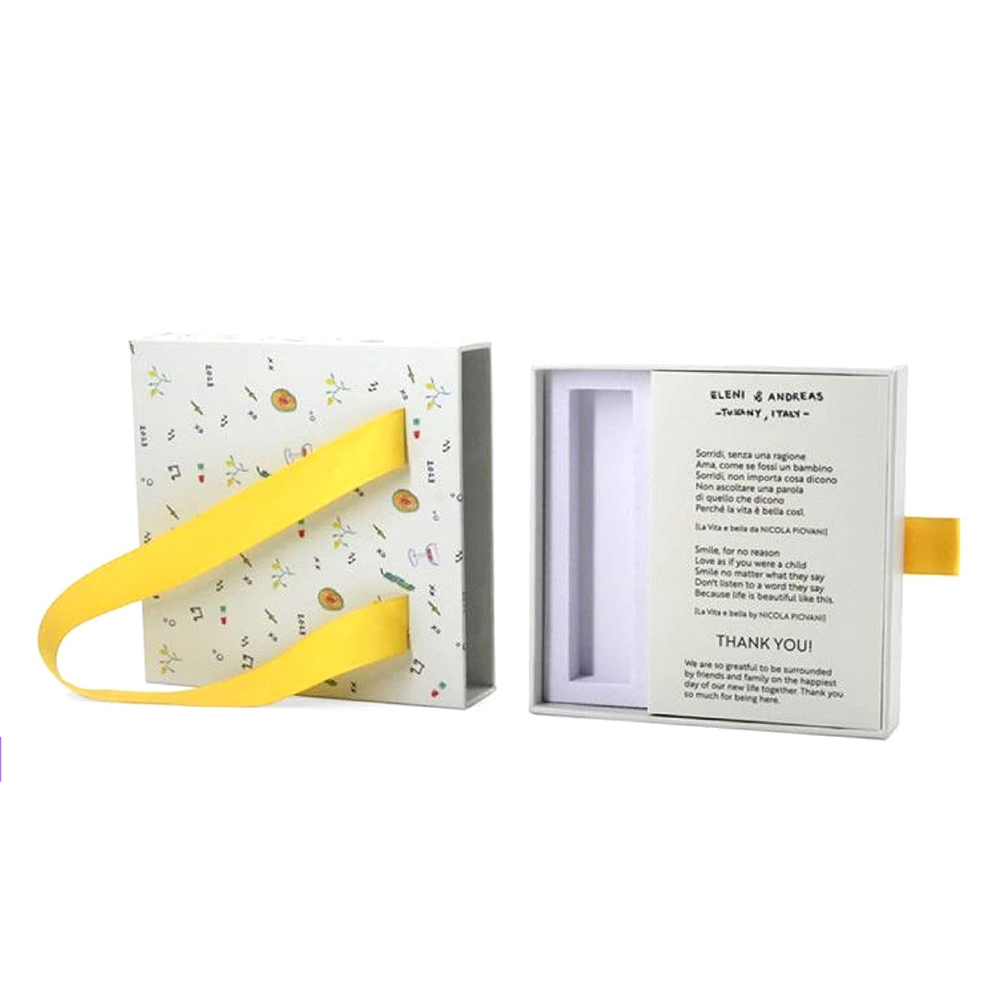

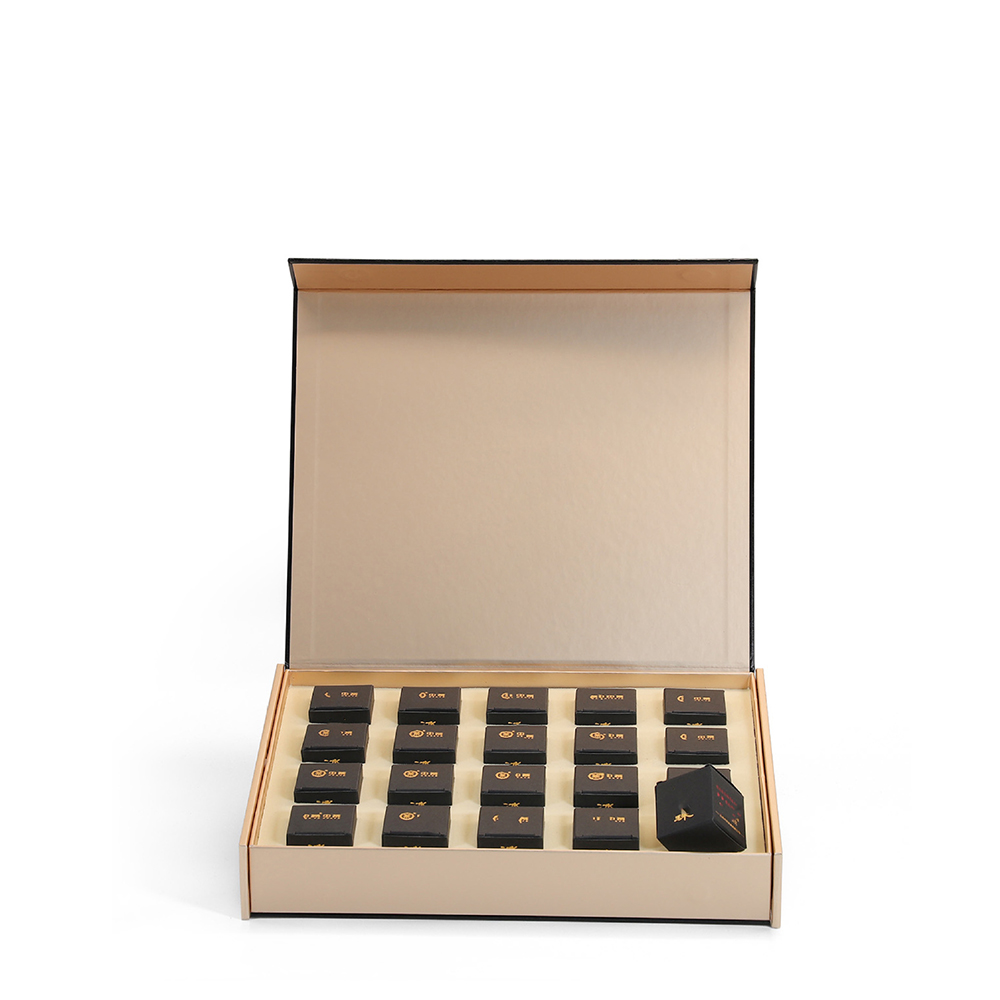

The “Lid and Bottom Box” structure (a design with a separate lid and base) addresses the pain points of traditional packaging, such as wrinkling and insufficient pressure resistance during transport. For instance, a certain brand’s patented packaging box employs a trapezoidal internal support cardboard and a Velcro fastening system, allowing the shirt to maintain its three-dimensional shape during transport, preventing the collar from collapsing. This structure also caters to the sense of occasion when opening—consumers can simply lift the top lid to clearly display the entire shirt without needing to fully remove the product, thereby reducing the risk of damage and enhancing the unboxing experience.

Compared to traditional plastic bags or flat paper boxes, the Lid and Bottom Box design ensures the shirt’s flatness through layered fixation (such as anti-slip textures and groove positioning), making it particularly suitable for the transport and display needs of high-end business shirts. The Lid and Bottom Box is made from lightweight, eco-friendly cardboard with a layered interior, improving load-bearing capacity by 30% and reducing the transport damage rate to below 0.5%.

2. Brand Empowerment: Dual Engagement of Visual Language and Emotional Resonance

The flat design space of the Lid and Bottom Box provides a three-dimensional expression platform for brand image. Luxury brands like Chanel have already validated the high-end feel of black and white minimalist colour schemes, while modern brands can deepen creativity in the following ways:

- Symbolic Graphics: Printing abstract geometric patterns or brand totems (like the evolution of Burberry’s check) on the box lid to strengthen visual memory.

- Material Collision: Shenzhen Yesheng Design Company suggests integrating matte paper bases with partial hot stamping techniques or combining bamboo fibre with biodegradable plastics to convey an eco-friendly concept.

- Interactive Narrative: The British Carton Company designed a packaging box for a custom shirt brand, featuring an AR trigger code printed on the inside of the lid, allowing users to scan and watch a designer interview video, turning the packaging into a carrier of the brand story.

Research indicates that 72% of consumers believe creative packaging directly influences purchasing decisions, and the “unboxing ritual” of the Lid and Bottom Box can extend user engagement time with the brand, enhancing emotional recognition.

3. Environmental Transformation: Innovative Practices in Sustainable Materials

The global packaging industry is rapidly transitioning towards a circular economy. The Lid and Bottom Box can achieve environmental upgrades through the following paths:

- Material Substitution: Using FSC-certified pulp, bagasse bio-based materials, or mycelium composite materials to replace non-degradable plastics. For example, a certain European brand launching a “zero carbon shirt box” in 2024 uses recycled cardboard and plant-based inks, reducing carbon footprint by 40%.

- Structural Optimisation: Extending the packaging lifecycle through modular design (such as removable liners). Users can repurpose the base box as a storage box and transform the lid into a picture frame, achieving “multiple uses from one box”.

- Supply Chain Collaboration: Manufacturers like Shanghai Chengjin Printing Technology have introduced “old for new” programmes, recycling old boxes to regenerate new packaging, forming a closed-loop system.

4. User Experience: A Comprehensive Upgrade from Functionality to Emotion

The Lid and Bottom Box significantly enhances user experience through detailed design:

- Portability: Adding anti-slip handles or magnetic closure designs for easy carrying by business people.

- Scene Adaptability: Categorised carrying bags (such as independent collar protection bags) meet the needs of various scenarios, including business travel and daily use.

- Sensory Stimulation: A certain Japanese shirt brand includes cedar wood chips in the box, releasing a natural fragrance upon opening, creating a “forest-like” unboxing experience.

5. Cost Efficiency: A Win-Win Strategy of Standardisation and Customisation

Although the initial mould costs for the Lid and Bottom Box are relatively high, its standardised production characteristics can significantly reduce marginal costs. For example:

- Modular Templates: Offering six standard box sizes, brands only need to customise surface printing, saving over 30% in costs.

- Smart Printing Technology: The HP Indigo digital printing machine supports small batch orders, catering to flexible needs such as limited edition holiday designs.

- Transport Optimisation: The foldable Lid and Bottom Box can be compressed to a flat state, reducing storage and logistics space requirements.

6. Future Trends: The Integration of Intelligence and Data

The iterative direction of the Lid and Bottom Box is deeply integrated with technology:

- Smart Sensing: Built-in NFC chips monitor temperature and humidity in real-time, ensuring the quality of high-end shirt fabrics.

- Data Tracking: QR code labels are linked to a blockchain system, allowing consumers to trace raw material origins and production histories.

- Interactive Marketing: Scanning the box lid pattern unlocks online customisation services, such as virtual fitting or membership points.

Conclusion

The creative value of the Lid and Bottom Box extends far beyond the packaging itself—it serves as a physical interface for brand storytelling, an emotional touchpoint in the user journey, and a practical example of sustainable business. From structural innovation to intelligent empowerment, its multidimensional innovations provide the shirt industry with a breakthrough from “product competition” to “experience competition.” In the future, with ongoing advancements in materials science and digital technology, the Lid and Bottom Box will redefine the concept of “Packaging as a Service,” becoming one of the core drivers of brand growth.